Results

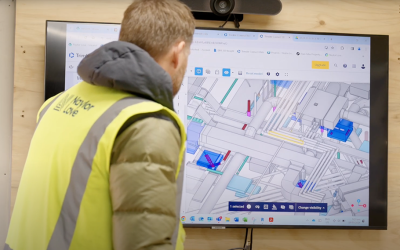

ACC Ōtepoti: Clash detection for safer services installation

On the ACC Ōtepoti project, the use of Building Information Modelling (BIM) and collaborative processes enabled the project team to focus on potential health and safety hazards that could occur during construction and installation of services, particularly in ceiling spaces. Working with a federated 3D model and facilitating open communication among stakeholders, including contractors and subcontractors, the team could thoroughly investigate and address potential risks before and during construction, creating a safer and more efficient work environment.

Helix Global: Prefabricated housing using BIM

Helix Global is pioneering New Zealand’s first fully off-site manufactured residential home. By leveraging Building Information Modelling (BIM) technology, the company has been able to address the unique challenges associated with prefabricated construction, transportation, and on-site assembly. The use of BIM has enabled Helix Global to enhance safety throughout the entire process, from factory manufacturing to final installation.

DBC Building Services: Using BIM to support older workers

In the mechanical services industry, experienced workers like Colin Graham, a contract pipe fitter and welder, are benefiting from the use of Building Information Modelling (BIM) and 3D modelling. These technologies allow older workers to continue contributing their valuable skills while minimising physical risks associated with working on-site. By enabling remote work and prefabrication, BIM and 3D modelling improve safety, efficiency, and knowledge transfer between older and younger workers.

ACC Ōtepoti: Experiences of a new BIM user

On the ACC Ōtepoti project, the introduction of Building Information Modelling (BIM) to a seasoned construction professional with 23 years of experience in traditional 2D environments has demonstrated the significant potential for improving safety planning, communication, and issue resolution. By leveraging the 3D model’s interactive capabilities, the team was able to visualise and address potential safety hazards, plan work methodologies, and effectively communicate complex issues across geographically dispersed team members.

City Rail Link: BIM simulation for driver training

For the Central Rail Link project, the BIM model is used as the basis for a virtual reality fly-through to educate train drivers and communicate project progress to the public. This innovative approach allows drivers to experience and prepare for potential hazards they may encounter during construction, enhancing safety and awareness. The 3D model is updated quarterly to reflect current site conditions, including temporary works, machinery, and permanent installations.

City Rail Link: Virtual reality (VR) worker induction

The City Rail Link (CRL) project in New Zealand has implemented an innovative virtual reality (VR) induction process for workers, leveraging Building Information Modelling (BIM) to create immersive training environments. This approach allows workers to experience and understand potential hazards and safety protocols in a risk-free virtual setting before entering the actual construction site. The VR induction process has proven particularly effective for workers unfamiliar with tunnel environments or those who don’t have English as their first language, ensuring a comprehensive understanding of safety procedures across diverse teams.

Watercare: Creating an information culture around BIM

In this case study, Farzam Farzadi of Beca discusses how Building Information Modelling (BIM) has been implemented on a number of projects for Watercare, a water utility company in Auckland. By embracing BIM as a culture and way of working, Watercare has been able to improve health and safety outcomes, reduce project risks, and enhance collaboration among project stakeholders.

ACC Ōtepoti: BIM in steel design and prefabrication

John Jones Steel has been using 3D modelling technology for over 20 years, with a strong focus on improving health and safety in construction processes. By leveraging Building Information Modelling (BIM), the company has significantly enhanced its ability to design safer construction methods, increase prefabrication, and optimise on-site assembly processes. This approach has led to improved safety outcomes for both workshop and on-site workers, as well as better project deliverables for clients and other subcontractors involved in their projects.

ACC Ōtepoti: Using BIM to test façade installation options

On the ACC Ōtepoti project, the construction team is using the BIM model to support visualisation, planning and communication, and to improve health and safety processes during the façade installation. When challenges arise, team members can use the model to visualise the problem and share information with others, and test possible solutions. Communication and collaboration are facilitated, making it easier to plan safe construction methodologies to mitigate hazards, with clear benefits for improved health and safety management.

ACC Ōtepoti: Contractor use of BIM for communication

Page contents BackgroundVideoApproachOutcomes and benefitsLessons learntBackground“BIM is the best communication tool...