Contractor / Subcontractor | Model visualisation for hazard identification

Description

Model visualisation in BIM is a powerful tool that helps to identify potential safety hazards early in the construction process. BIM provides a virtual representation of the project, which users can explore, look at from different angles and use to gain a shared understanding of how construction will take place. The model may include specific safety information, such as hazard tags, exclusion areas and temporary structures needed during construction.

Hazard identification involves looking at the project’s design and proposed construction methodology to find situations that could potentially harm workers. Using model visualisation, safety professionals and project teams can get a clearer picture of the construction site and its hazards, so it’s easier to find safety issues, carry out risk assessments and come up with ways to control those risks.

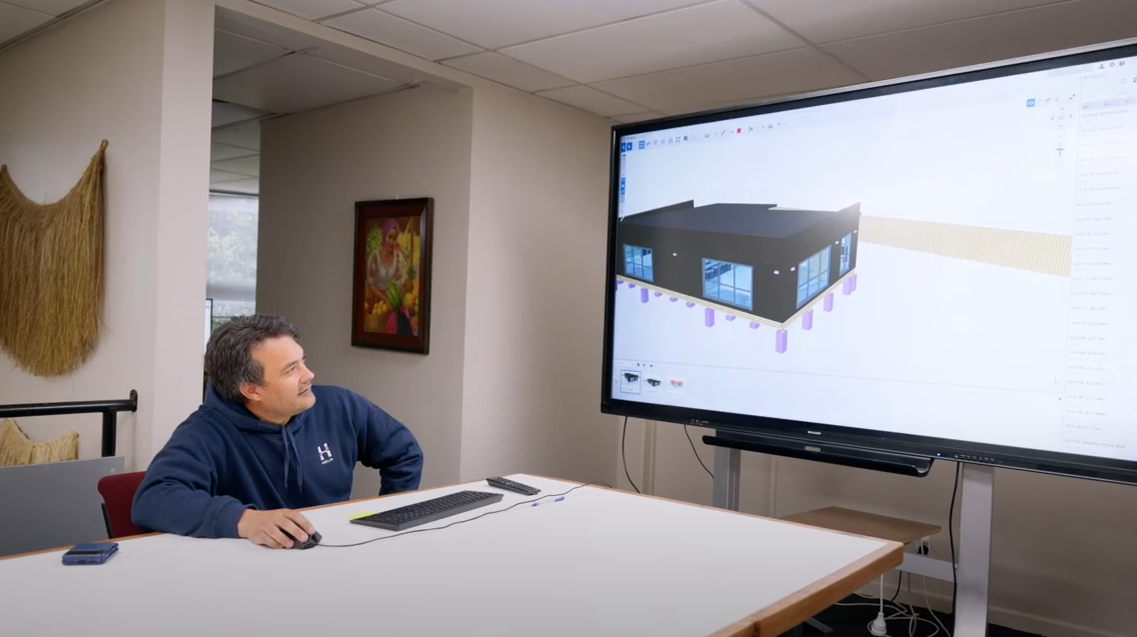

Temporary works planning using IDD Tech’s ToBe Builder software

Case studies

Uses and benefits for health and safety

- Early identification of hazards: The model can be used to visualise potential hazards such as unprotected edges, collision points between equipment, or areas with limited access for emergency response, before construction begins. Identifying issues early allows for modifications to eliminate or mitigate hazards before workers encounter them.

- space

- Site hazard mapping: Model visualisation enables the creation of a detailed hazard map of the construction site, with hazards such as fall risks, electrical hazards, or high-traffic areas tagged and highlighted directly within the model. This visual representation of hazards promotes greater awareness and helps prioritise safety measures.

- space

- Collaborative approach to risk assessment: Model visualisation facilitates collaborative sessions where project stakeholders from different disciplines can come together to review the model and identify hazards specific to their areas of expertise. This multidisciplinary approach captures a wide range of perspectives and ensures a comprehensive assessment of risks, while the model visualisation ensures a shared understanding of the issues under discussion.

- space

- Improved worker engagement and participation (WEPR): Model visualisation actively enables workers to be involved in identifying hazards and proposing mitigations, making it more likely that these will be used by workers on site.

- space

- Improved site inductions: Model visualisation can provide new workers and visitors with a view of the site and guide them through various activities carried out in different parts and stages of the build. It can clearly represent access routes, exclusion zones, equipment movements and locations and other key information.

- space

Technology/techniques

- Virtual walk-throughs: The model can be used to conduct virtual safety reviews, allowing the team to identify hazards and evaluate the effectiveness of proposed safety measures in a realistic, immersive environment. This is particularly useful for identifying hard-to-spot hazards or planning for complex tasks and allows safety considerations to be integrated before work starts on site, rather than being an afterthought. Collaborative reviews using the model make it easier for multiple participants to be involved, including specialists who may not be on site.

- space

- Sight line analysis: The model can be used to analyse sight lines and visibility on the construction site, identifying areas where workers may have obstructed views or limited awareness of potential hazards. This helps plan site logistics, equipment placement and safety barriers.

- space

- Hazard mapping: By analysing data on past incidents, near misses and high-risk activities, teams can create a hazard heat map that highlights areas of the site with the greatest safety risks. This information can be overlaid onto the model, providing a clear visual guide for focusing safety efforts and resources where they are needed most.

Model/data requirements

The basic requirement for effective hazard identification is a federated BIM model that is complete and accurate, and represents all relevant aspects of the project, including architectural, structural, mechanical, electrical and plumbing models from trades and consultants.

- space

- The model should be developed to an appropriate level of detail (LOD) that supports hazard identification.

- space

Information that adds value to hazard identification is not always included in a model and will require greater investment of time and resources into the model creation, but will support more thorough analysis of project risks. For example:

- space

- Including site logistics and phasing information in the model adds a lot of value for hazard identification, especially temporary works, access routes, material storage areas and construction sequencing.

- space

- Elements can be modelled to include hazard-specific data attributes, such as material properties, dimensions, clearances and load capacities, which are relevant to identifying potential hazards.

- space

- Ideally, the model should be regularly updated to reflect the latest design changes and construction progress, ensuring that the visualised information is current and reliable.

- space

Visualising complex operations – for example, double lifting of long-span structures – may need a dedicated resource for precise modelling and simulation. This level of awareness of the construction task will greatly improve the health and safety in construction methodology.

Hardware and software requirements

Software needs depend on whether the user is creating the model visualisation or using a model that has already been created.

- space

- BIM authoring software: A BIM authoring tool, such as Autodesk Revit or Graphisoft ArchiCAD, is needed to create and develop the 3D model of the construction project.

- space

- Temporary works modelling: A variety of software tools are available to create temporary works content, from premade components in Trimble’s 3D Warehouse to sophisticated designs using Autodesk’s Revit. Many plant and equipment models are also available on the web. Many manufacturers create a 3D model of their product, to be used in spatial applications like construction planning.

- space

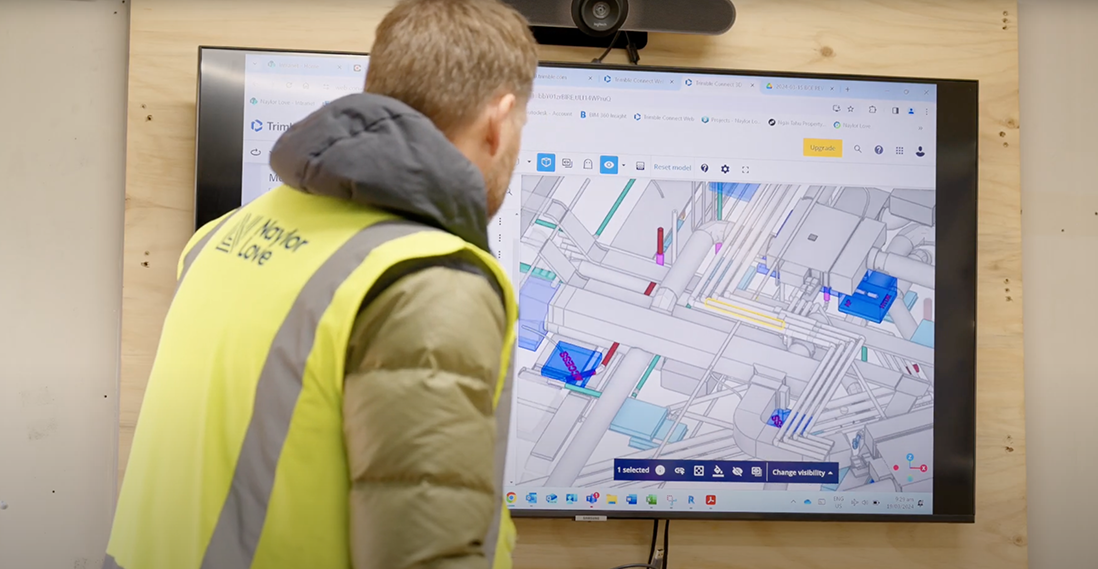

- Shared model platform: A common data environment (CDE) or model coordination platform, such as Autodesk BIM 360, Trimble Connect or Revizto, is necessary for project stakeholders to collaborate and share the model. These platforms enable multiple users to simultaneously access, review and contribute to the model, for example, to add notes and markups for issue tracking, or to connect to other project data sources, such as safety databases or document management systems.

- space

- Model viewer: Many free model viewers are available that allow project stakeholders to open and navigate through BIM models, though typically they do not have interactive features, such as the ability to create custom views or markups.

- space

Hardware requirements scale with the complexity of the model. The more sophisticated the contents, the more processing power it will require. Any workstation that interacts with the model needs to have sufficient memory and graphics capable of the task.

Contract/procurement implications

Clearly, hazard identification using BIM requires a BIM-enabled project.

A project BIM brief defines the client requirements and expectations for a project with regard to BIM. A BIM Execution Plan (BEP) outlines how a BIM project will be executed, managed and delivered. To enable hazard identification, these documents should identify that BIM is a requirement for the main contractor and trades, and that hazard identification is one of the main purposes of the BIM implementation.

Identifying the BIM intentions early in the procurement process enables the delivery team to work with consultants and subcontractors to develop BIM resources. The cost and risk should not fall solely to contractors but be spread across all stakeholders.

Roles and responsibilities

| BIM manager |

Sets up files and facilitates information exchange, checks models from suppliers and designers for compliance in the BIM Execution Plan, sources temporary works models and combines models from trades and consultants. |

| Construction project manager |

Uses the model to identify hazards based on their own experience and leads methodology review sessions with the project team, to identify any potential safety clashes or concerns. ㅤ |

| Trade contractors |

Uses the model to understand their work area, coordinate with other trades, identify hazards and communicate safety concerns or suggestions back to the project team. ㅤ |

| Health and safety manager |

Works with the project team, using the model to identify hazards and ensure mitigations are in place, and participates in HSbD processes by identifying specific construction risks not considered by the design team. Uses the model to facilitate WEPR. ㅤ |

Training requirements

Training should be hands-on and project-specific, with ample opportunity for users to practice navigating and interacting with the actual project model.

In most cases, the best approach is to learn through doing and observing others using the model. For users who have never used BIM before, it may be useful to provide an overview of BIM fundamentals and an overview of BIM concepts, terminology and benefits to help users understand the value of model-based communication and how it fits into the overall project. This may encourage them to use the model and think about what else they can use it for besides hazard identification.

It may be helpful to identify BIM champions who can serve as a resource for others and support ongoing model use.

Future directions

Creating a construction model requires data and information from everyone involved in a task, which can require a different approach to managing and sharing project information. Once established, it brings benefits to the whole delivery team.

Outputs from the model, such as animations and flythroughs, help workers to visualise the environment, identify potential hazards and acknowledge the scale of the risk. Future approaches include the use of virtual reality (VR) and augmented reality (AR) to give project participants a more immersive experience within the model. This can increase awareness of hazards by creating a greater sense of the workspace, particularly for constrained work areas and situations where multiple hazards may interact.