Results

Dunedin Hospital Outpatients Building: Drilling with the Hilti semi-autonomous robot

Page contents BackgroundVideoApproachOutcomes and benefitsLessons learntBackgroundThe new Dunedin Hospital outpatients...

Steel and Tube: A new resource for health and safety

Steel & Tube, a reinforcing steel fabricator in New Zealand, has successfully adopted BIM technology to streamline their processes, enhance product delivery, and improve health and safety outcomes. Using 3D modelling software like Tekla Structures, they can create detailed visualisations of complex structures, plan sections of work for prefabrication, and share models with clients and on-site teams. This approach has resulted in substantial reductions in errors, increased efficiency, and the creation of safer working environments for project stakeholders.

City Rail Link: BIM for safety on Auckland’s City Rail Link project

On the City Rail Link project in Auckland, New Zealand, the project team has utilised BIM in various ways to improve safety planning, design coordination, and worker training. Using 3D models, point cloud data, virtual reality, and on-site digital tools, the team has been able to identify and mitigate potential safety hazards, standardise tunnel signage, provide immersive training experiences for workers, and enhance driver awareness. The approaches used on this large-scale, complex project can be adapted and applied to projects of any size, demonstrating the versatility and value of BIM in promoting safety in construction.

Naylor Love: Health and safety manager’s perspective on BIM

Jen Dransfield, a Health and Safety Advisor at Naylor Love, shares her perspective on how BIM can be used to enhance safety outcomes for workers on construction sites. By using BIM to provide “environmental feedback” and enable collaboration between different parties, the project team has been able to identify and mitigate risks, particularly for challenging projects like the Christchurch Cathedral Reinstatement and the Tower 3 build. Jen’s experience demonstrates the potential of BIM as a powerful tool for improving health and safety on the ground in construction.

Watercare: Digital engineering to support health and safety on infrastructure projects

Watercare, a water utility company in New Zealand, has implemented a digital engineering program to improve health and safety, reduce carbon footprint, and decrease cost and time on their infrastructure projects. Using BIM and data-driven approaches, Watercare aims to enhance awareness, collaboration, and consistency across their supply chain and project lifecycle.

Auckland Airport: Seeing the unseen

At Auckland Airport, the digital engineering team has utilised BIM and gaming software to improve underground utility mapping, visualisation, and construction site safety planning. By combining existing data with 3D scans, creating interactive models, and simulating various scenarios, the team has been able to reduce risks associated with underground services, enhance project team collaboration, and optimise site safety management.

ACC Ōtepoti: Designer & contractor model interaction for safety planning

On the ACC Ōtepoti project, the use of BIM has enabled effective collaboration between the structural steel subcontractor, John Jones Steel, and the permanent works engineer to address health and safety and buildability concerns. By sharing model files of their bolting tools, John Jones Steel has allowed the engineer to test and validate the design of frame braces to ensure safe and efficient construction.

ACC Ōtepoti: Contractors using BIM for health and safety

On the ACC Ōtepoti project, BIM models help the site team to identify and mitigate potential hazards and pinch points early. By allowing contractors and subcontractors to improve the accuracy of site set-out and communicate work plans and safety constraints effectively with the project team, BIM is helping to increase awareness and reduce rework on site. The ability to use mobile devices for digital access to project information also improves supervision and reduces the need for supervisors to leave the work area to get information. Combined, these benefits are leading to improved hazard management and safety performance.

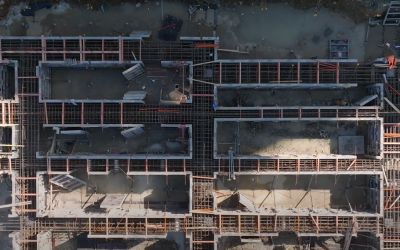

ACC Ōtepoti: Collaborative use of BIM in reinforcing

On the ACC Ōtepoti project, multiple consultants and contractors have collaborated using Building Information Modelling (BIM) to improve the design, coordination, and construction of reinforcing steel. By using BIM to model the reinforcing in 3D, the project team was able to anticipate connections between different elements, detect clashes, and prefabricate reinforcing cages in a controlled environment. This has led to improved efficiency, quality, and safety on the project.

ACC Ōtepoti: Collaborative use of BIM in safety planning for foundation reinforcing

On the ACC Ōtepoti project, consultants and contractors have collaborated using BIM to improve safety planning, particularly for the complex reinforced concrete foundation beams. By using 3D models to visualise the dense reinforcement, coordinate the penetrations, and assess the prefabrication opportunities, the project team has been able to reduce manual handling risks, improve the quality of the work, and streamline the construction process.