Results

University of Auckland: Using BIM to engage a Facilities Management team in Safety in Design

The Old Choral Hall refurbishment project demonstrates how Building Information Modelling (BIM) can reveal safety issues that might be overlooked in traditional 2D drawings. Through the use of BIM visualisation, the project team identified and resolved a significant maintenance access hazard by relocating a fan unit from a high-risk position to an accessible floor-level location, showcasing the value of BIM in health and safety by design.

University of Auckland: Using BIM for Facilities Management safety planning

On various projects, including the historic Old Choral Hall renovation, the University of Auckland Facilities Management (FM) team has implemented a comprehensive Building Information Modelling (BIM) review process to enhance safety and maintenance accessibility. Using 3D modelling capabilities and regular coordination meetings with stakeholders, the team has brought facilities management considerations into the design review process, ensuring safer and more efficient building operations and maintenance procedures.

University of Auckland: BIM visualisation for Facilities Management

This case study examines how BIM is being used to improve safety in facilities management operations at the University of Auckland, particularly focusing on maintenance access and risk assessment.

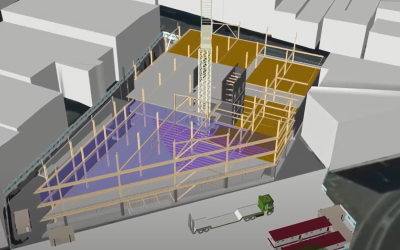

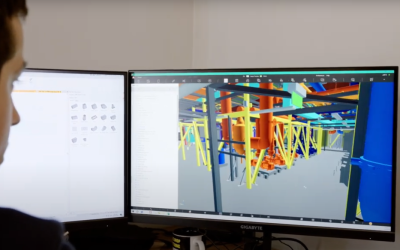

ACC Ōtepoti: Use of a 4D animation for planning

The ACC Ōtepoti project team used 4D BIM technology to support their construction safety planning, particularly focusing on structural steel and floor slab installation. By creating an animation of the BIM model visualisation against the project timeline, the team could identify and address potential safety risks months before construction began. This approach helped to clarify problems with the planned sequence of works, enabled better coordination between different trades, and helped create safer working conditions for everyone involved in the construction process.

ACC Ōtepoti & Court Theatre: Use of BIM to improve site safety culture

DBC Building Services used Building Information Modelling (BIM) and advanced manufacturing techniques to improve safety and efficiency in the mechanical services installation for the Dunedin Outpatients Building. Using 3D modelling and direct-to-fabrication processes, the team significantly reduced on-site work at height, improved accuracy, and created a safer work environment.

ACC Ōtepoti: Overlay of BIM model and reality capture using OpenSpace

On the ACC Ōtepoti project, the implementation of OpenSpace BIM+ technology has given the project team a new tool to assist in construction verification and safety monitoring. By overlaying BIM models with reality capture on site, the team can remotely verify installation accuracy, identify potential conflicts, and reduce the need for hazardous physical inspections. This approach improves both construction accuracy and worker safety on the project.

Court Theatre: Creating a culture of collaboration

On the Court Theatre project, the use of Building Information Modelling (BIM) has fostered a more collaborative culture among subcontractors, encouraging them to consider the work of other trades and coordinate their efforts more effectively. By providing a holistic view of the project and enabling better communication, BIM has helped to break down the “first in best dressed” mentality and promote a more cooperative approach to construction delivery, leading to improved safety and efficiency on site.

Court Theatre: Pre-planning for safer work

On the Court Theatre project in Christchurch, New Zealand, the use of Building Information Modelling (BIM) enabled the project team to proactively plan for safer working conditions. By leveraging 3D modelling and collaborative processes, the team identified potential issues early and developed strategies to mitigate risks. This approach led to reduced need for working at height, minimised manual handling, and optimised installation sequences, resulting in a safer and more efficient worksite.

Dunedin Hospital Outpatients Building: Subcontractor modelling and prefabrication

DBC Building Services used Building Information Modelling (BIM) and advanced manufacturing techniques to improve safety and efficiency in the mechanical services installation for the Dunedin Outpatients Building. Using 3D modelling and direct-to-fabrication processes, the team significantly reduced on-site work at height, improved accuracy, and created a safer work environment.

ACC Ōtepoti: Contractor methodology design and hazard ID

On the ACC Ōtepoti project, a 5.6-meter void existed below the service deck on the top floor. The use of Building Information Modelling (BIM) enabled the project team to identify and address potential health and safety hazards associated with wall construction and services installation onto this space. By using the 3D model to facilitate open communication among stakeholders, the team could thoroughly investigate and address potential risks and possible alternatives before construction began, leading to a safer and more efficient building process.