Designer | Model visualisation for planning

Description

The early design phases offer the optimal opportunity for comprehensive safety planning in construction projects. As design and construction progress, the cost and difficulty of implementing safety measures increase significantly. Projects that are well-planned from a safety perspective tend to be safer because hazards have been considered in advance and decision-making is more informed.

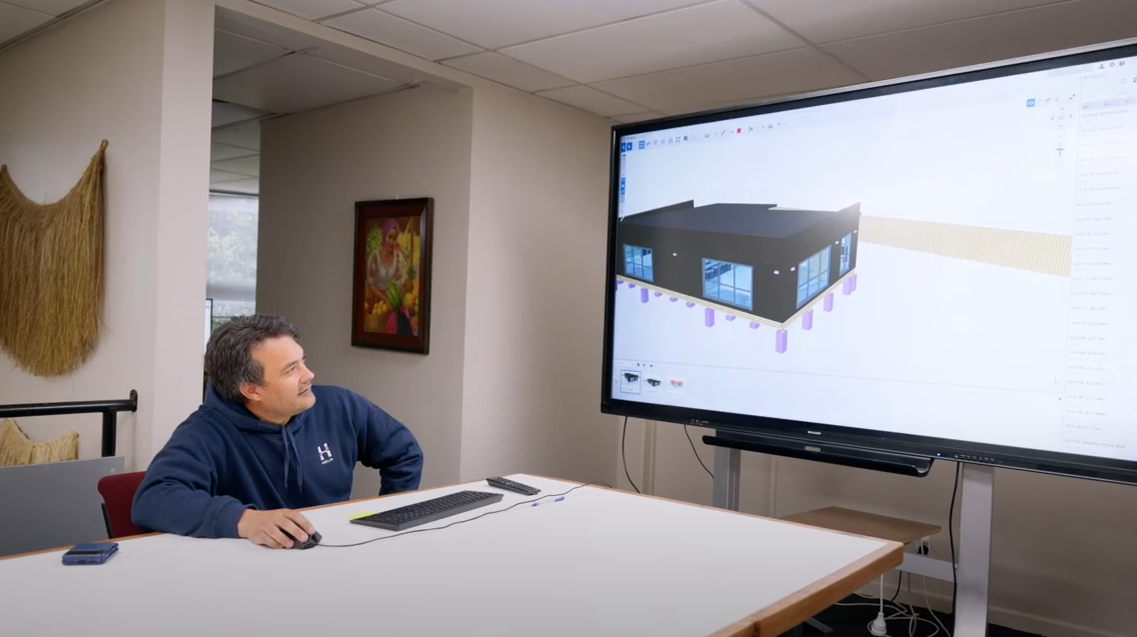

Building Information Modelling (BIM) provides a powerful visual tool during the design phase to support thorough safety planning. The BIM model allows stakeholders to identify potential hazards, plan mitigation strategies, and make informed decisions about safety measures long before construction begins. As the design evolves, the safety plan can be continually refined using BIM visualisation, ensuring that safety considerations remain at the forefront throughout the iterative design process.

Health and Safety by Design (HSbD) processes are greatly enhanced through BIM visualisation, particularly in supporting safety planning. The visual nature of BIM models facilitates meaningful input from stakeholders outside the core design team, enabling a more holistic approach to safety planning that addresses potential challenges in the construction and operational phases.

Case studies

Uses and benefits for health and safety

- Early identification of potential hazards on site such as fall risks, confined spaces, or areas with limited access, so safety processes can be planned before construction begins. Using the model, designers can spot issues that might be overlooked in traditional 2D drawings, leading to more thorough and effective safety plans.

- space

- Planning of safe access routes and work areas for worker movement, material handling, and equipment operation, e.g. ensuring adequate space for scaffold erection or crane operations, reducing the risk of accidents due to congested work areas.

- space

- Provides a common platform for all stakeholders to review and contribute to safety plans. The visual nature of BIM models makes it easier for non-technical stakeholders to understand and engage with safety discussions.

- space

- Helps integrate safety features into the design, rather than adding them as afterthoughts. This might include designing in permanent anchor points for fall protection, ensuring adequate space for safety equipment, or planning safe maintenance access to building systems.

- space

- Improves planning for safety resource allocation, helping to identify what safety equipment is need and where it is best located.

Technology/techniques

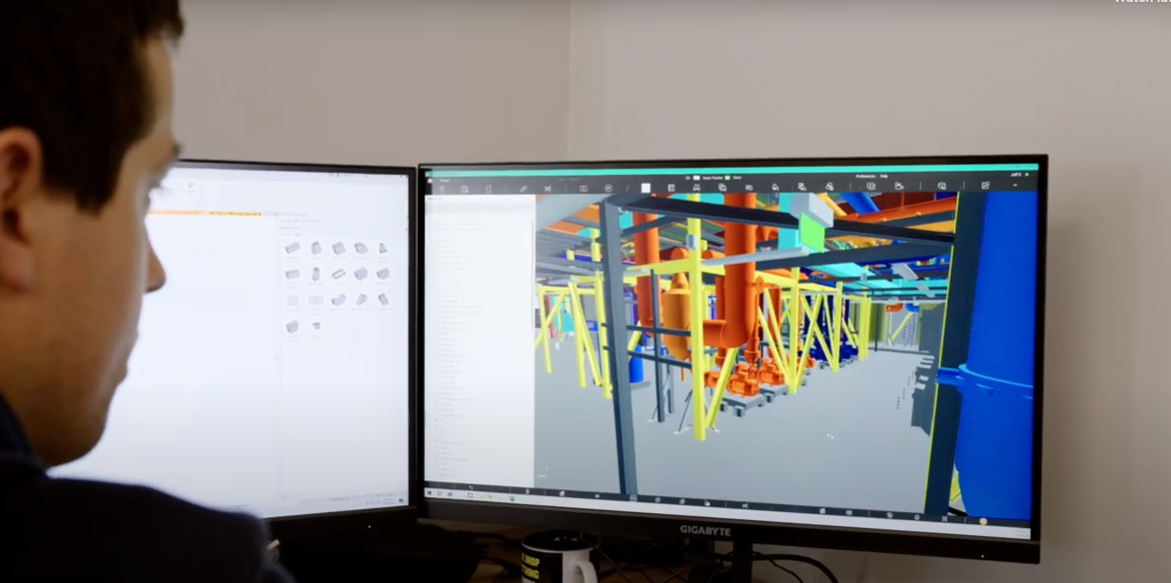

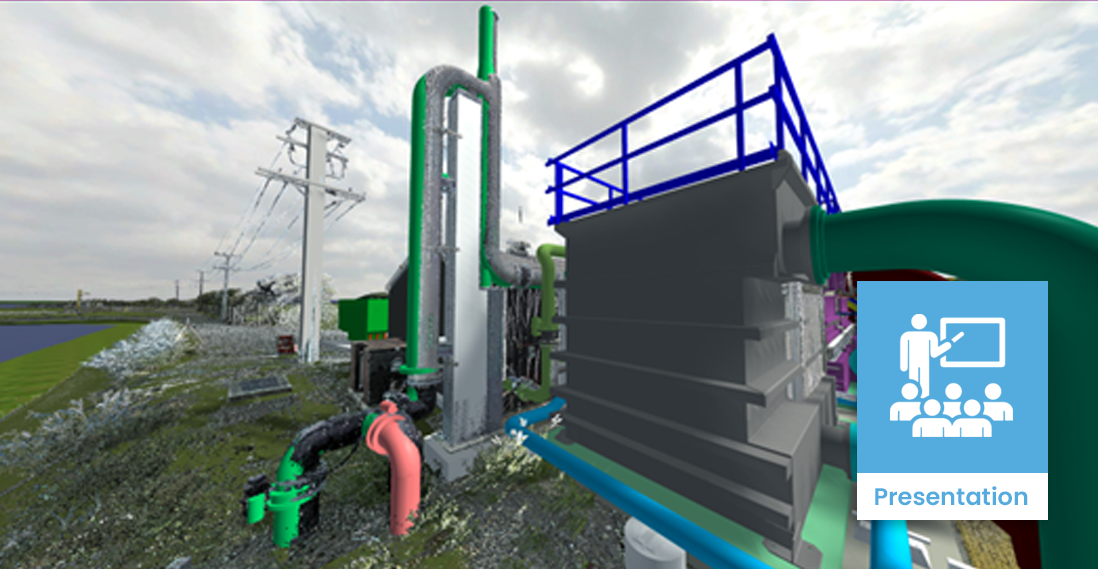

Model visualisation tools allow the federated BIM model created during design to be used as a platform for safety planning. By combining the model with supporting visualisations like site scans and topographical data, a comprehensive digital representation of the project can be created.

Safety planners can use this federated BIM model to identify and highlight potential hazard zones. These might include areas with fall risks, locations requiring specific safety equipment, or zones with restricted access during certain construction phases. By visually tagging these areas in the model, the safety plan becomes an integral part of the project’s digital representation.

Safety-related metadata or attributes can be added to model elements, for example, fire-rated structures can be color-coded, or equipment can be tagged with specific safety requirements. This ensures that safety considerations are visible and easily accessible during design reviews and decision-making processes.

Model/data requirements

Effective safety planning through BIM visualisation requires the design team to generate models with sufficient detail to identify potential hazards. While LOD 100 and LOD 200 models can provide a good starting point, safety planning may require additional detail in critical areas.

The model can be expanded to include not just the permanent building elements, but also essential temporary structures, construction equipment, and site logistics information that are useful for comprehensive safety planning. This might involve creating libraries of common construction equipment and safety features that can be easily incorporated into the model.

Commonly used file formats like .ifc or .rvt are suitable for model visualisation, but it’s important to ensure that safety-related data can be properly transferred between different software platforms. This might require the development of custom data fields or the use of standardised safety classification systems within the model.

Hardware and software requirements

Most modern computers can handle the visualisation tasks required for safety planning. The priority is ensuring easy access for all stakeholders involved in the safety planning process, including those who may not be regular BIM users.

Visualisation software should offer both online and offline access, allowing safety planning sessions to be conducted in various settings – from office to site meetings. Mobile compatibility is particularly valuable, enabling on-site safety reviews and real-time updating of safety plans as conditions change.

Some advanced safety planning techniques, such as automated clash detection between construction activities and identified hazard zones, may require more powerful hardware or specialised software. However, these tools are becoming increasingly accessible and user-friendly.

Contract/procurement implications

To ensure effective use of BIM visualisation for safety planning, the project’s BIM Brief and BIM Execution Plan (BEP) should explicitly include safety planning as a key BIM use. The BEP should outline how safety information will be incorporated into the model, who is responsible for maintaining this information, and how it will be shared among project stakeholders.

Contracts should specify deliverables related to safety planning, such as phase-specific safety plans derived from the BIM model. Consider including requirements for regular safety planning reviews using the BIM model as a collaborative tool.

Early contractor involvement should be strongly considered in the procurement strategy to maximise the benefits of BIM visualisation for safety planning. This allows construction expertise to inform safety decisions when changes are most cost-effective.

The NZCIC guidelines, commonly used for contract and procurement in New Zealand, should be updated to include specific requirements for BIM-based safety planning at each design stage.

Roles and responsibilities

| Design team |

Responsible for incorporating safety considerations into the BIM model to support safety planning. |

| Design BIM manager |

Ensures that safety-related information is properly integrated into the federated model and accessible for planning purposes. ㅤ |

| Client/owner |

Ultimately responsible for ensuring that thorough safety planning is conducted and that the resulting plans are implemented. ㅤ |

| Project manager |

Facilitates safety planning sessions using the BIM model and ensures that safety plans are integrated into overall project planning. ㅤ |

| Construction manager (if involved early) |

Provides input on construction methodologies and their safety implications during the planning process. ㅤ |

| Facility manager |

Contributes to long-term safety planning, ensuring that operational safety is considered from the design stage. ㅤ |

Training requirements

Basic training in navigating a BIM model viewer is essential for all stakeholders involved in safety planning. This ensures that everyone can actively participate in identifying hazards and proposing solutions.

Health and Safety professionals may require additional training in how to effectively use BIM tools for safety planning. This might include courses on visualisation or specialised safety planning software.

The project BIM Manager or similar role would need to be proficient in creating and managing model views specifically for safety planning purposes. This might involve learning how to incorporate safety-specific metadata into the model.

Future directions

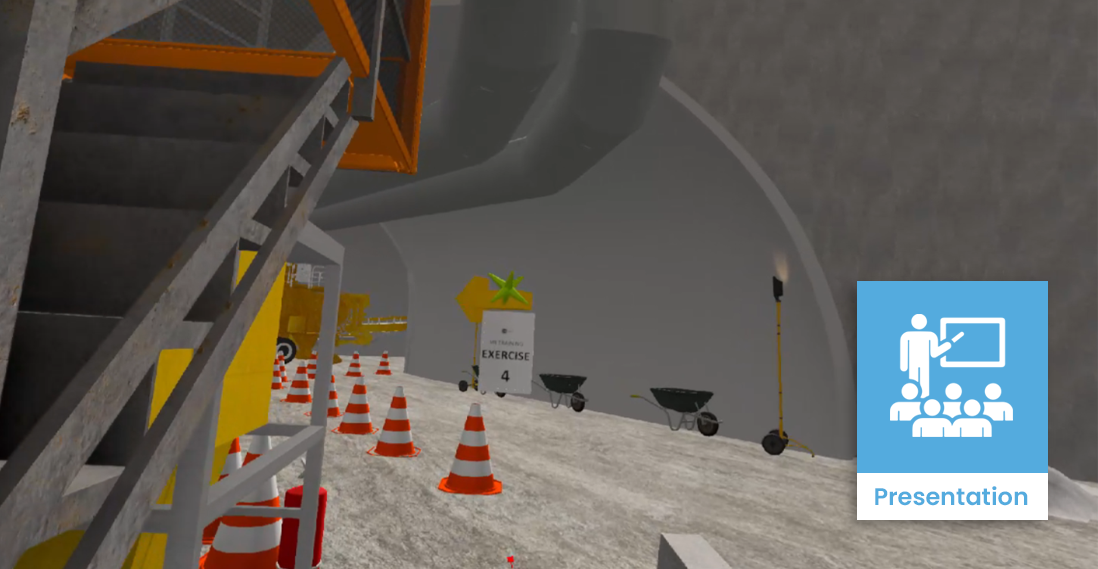

As BIM technology continues to evolve, more advanced tools are being specifically designed for safety planning. These might include AI-assisted hazard identification or VR-based safety training simulations using the project’s BIM model.

Integration between BIM and real-time site monitoring systems will allow for more dynamic safety planning, with the ability to update plans quickly in response to changing site conditions.

Standardisation of safety planning processes within BIM will likely emerge, facilitating better knowledge sharing between projects and contributing to continuous improvement in construction safety across the industry.