Owner / Client | Time based planning for safety planning

Description

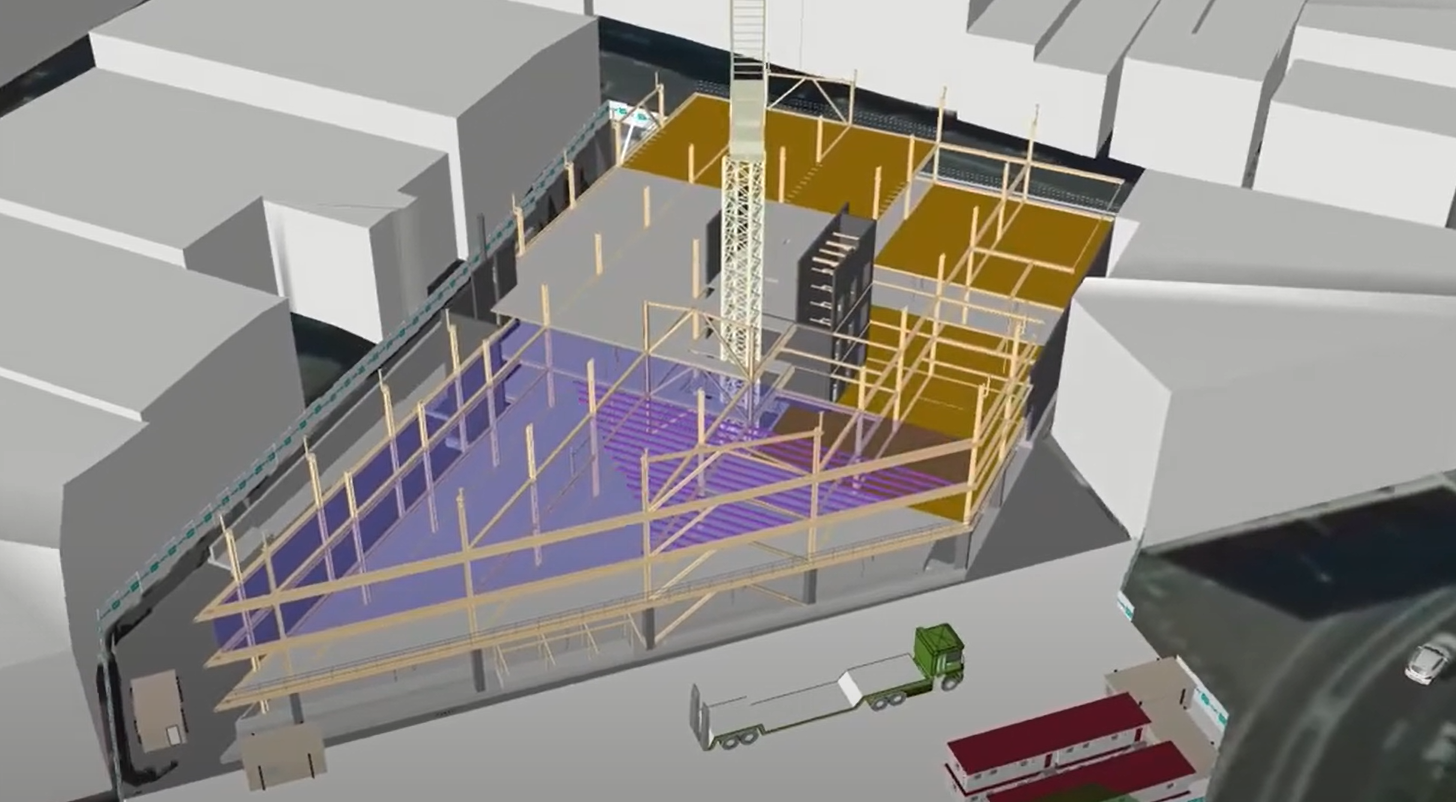

Time based planning, also called 4D modelling, combines traditional delivery planning with the 3D spatial elements of a BIM model. This approach can promote more proactive risk mitigation.

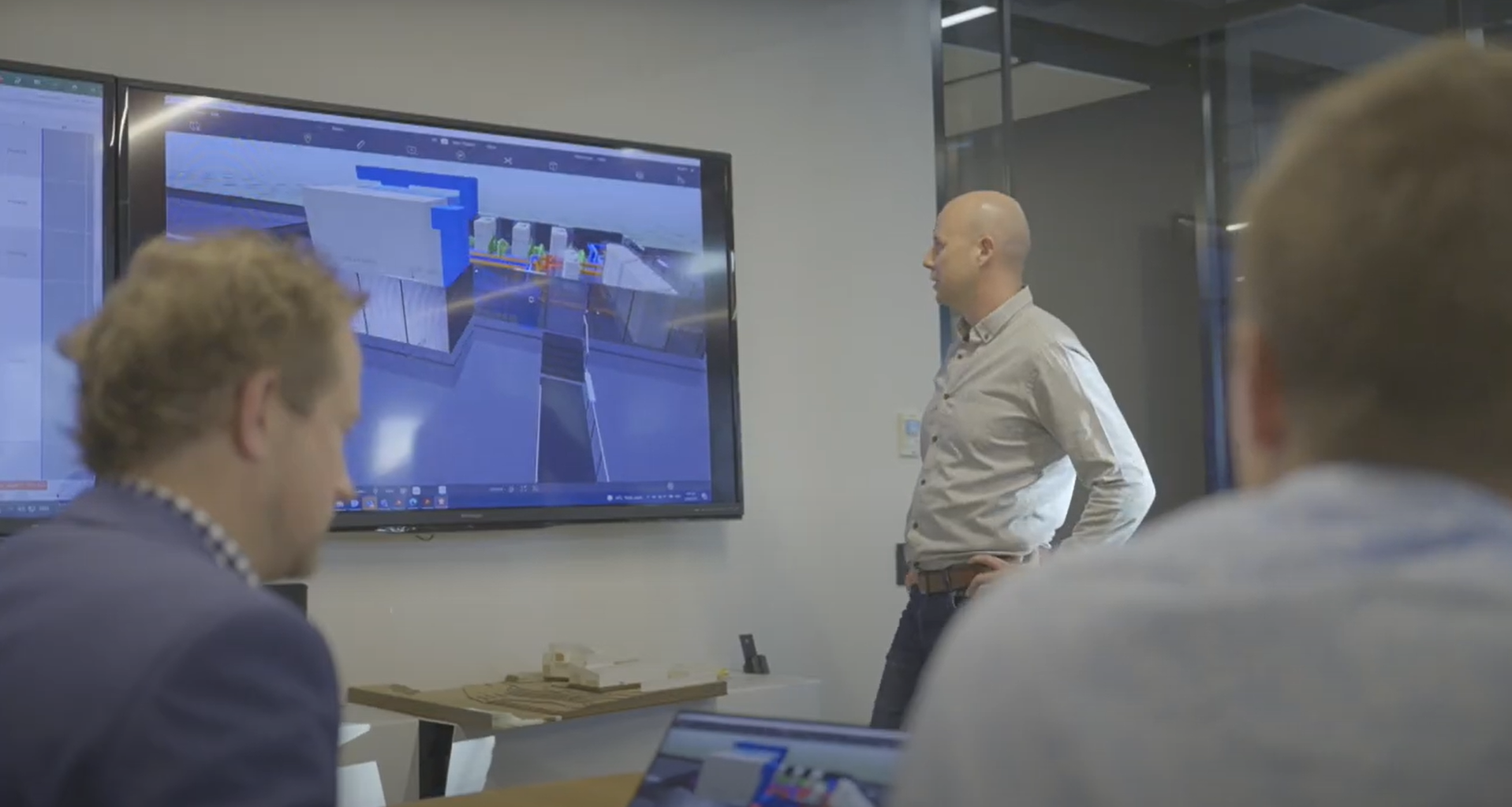

Adding time to a 3D model is increasingly used by complex projects as a means to communicate construction sequencing. The technique provides teams with a detailed visual representation of the build, where they can rehearse construction processes before actual construction begins. For an owner or client, time-based planning provides an easily communicated view of the planned construction process, which can be used to evaluate contractors’ safety plans and capabilities.

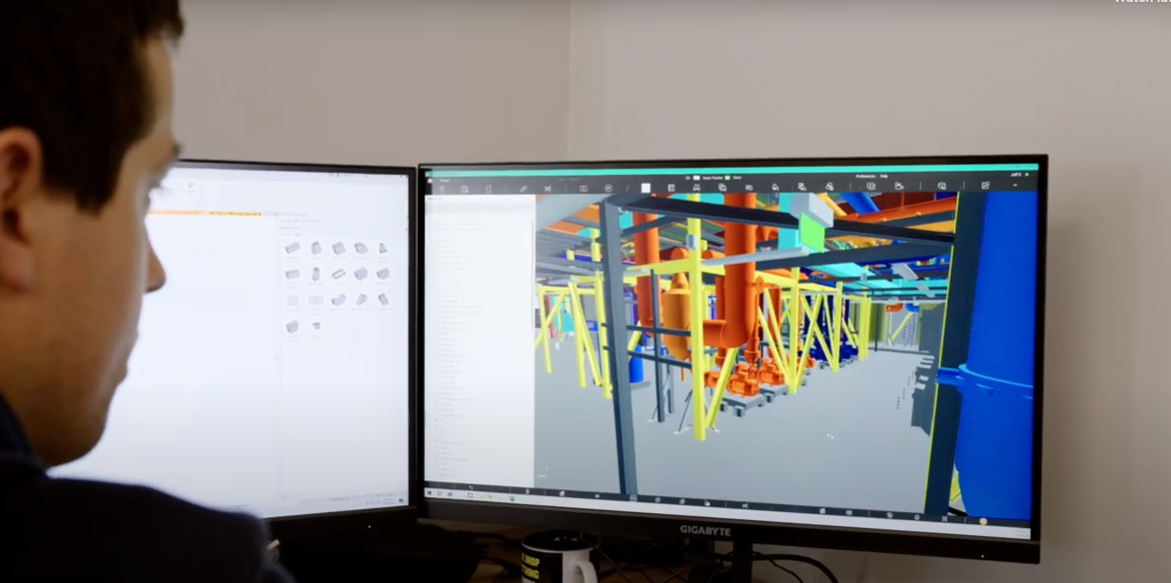

The combination of BIM authoring, scheduling software, 4D modelling tools and gaming technology can create a highly interactive environment that enables everyone in the construction team to more clearly look at health and safety factors on site.

Case studies

Uses and benefits for health and safety

- Improves health and safety planning by being to see a detailed view of the construction at any point in time.

- space

- Supports adherence to safety protocols by providing a visualisation of safety measures and timelines, including interactions between activities and risks of partially completed works that may not be visible in a static model representation.

- space

- Encourages site planners, project managers, foremen, and site workers to play a role in health and safety planning by being able to walk around the digital site at a chosen point in time to identify any potential risks. This creates greater engagement in the process and a more collaborative approach to risk mitigation.

Technology/techniques

Many 4D planning packages focus on construction sequencing and a high-level view of the model. Using 4D planning to improve safety planning requires technology that enables a first- or third-person view of the model to give the feeling of walking around a site.

This enables a more realistic approach to identifying issues by having the viewpoint of a person and considering the project in greater detail than a traditional top-down 2D site safety plan.

Planning software that creates a photorealistic environment is especially useful when using the models for health and safety planning – it leaves little to the imagination and makes it easier to spot potential hazards.

It is also possible to use BIM viewing tools that are not specifically intended for 4D planning. Such tools lack a link to the schedule, so the technique layers or filters properties that enable the viewer to toggle through construction stages. While this achieves the effect of a time-based model, it requires more manual processes, making it more suitable for smaller scale projects where the cost of specialist 4D tools isn’t unjustified.

Model/data requirements

Models must contain sufficient detail that users can gain an effective understanding of the site. Models should also ensure elements are correctly classified and located on the correct building level.

While data cleanliness is not a prerequisite for 4D planning, a clean model makes the process of establishing a time-based model much more efficient. A well-structured model makes it easier to isolate elements, for example by type, building level, area, load-bearing status, and so on. This helps when linking the model to tasks in the schedule, which follow a logical sequence for constructing the building, floor by floor, element by element, building shell or interior, etc.

It is important to have a library of common site equipment and accessories, such as machinery, safety barriers, signs, traffic management objects, etc. These can then be dropped into the 4D model to help build up a more realistic site.

If designers and contractors use different authoring software to model elements, they should agree on an open model exchange format, such as Industry Foundation Class (IFC). Exchanging schedules between software is typically done using the XML file format.

The construction schedule must be imported into the viewing software to enable the look of a stage-based model. When the project doesn’t use specialist 4D software, the schedule can structure the layering and element filters.

Hardware and software requirements

Several software tools are available for 4D planning, either as a desktop solutions or cloud-based platform. However, not all 4D tools are tailored to health and safety planning.

To gain a more detailed view of the construction site and plan the events that occur outside of the typical construction sequencing model, it is recommended to look for a tool with dedicated health and safety planning functions. These often come with a library of standard equipment and machinery, making it much easier to get started.

Hardware requirements depend on whether desktop or cloud-based software is used and the size and complexity of the model files. When using a desktop-based solution and large model files, a high-performance workstation with a dedicated graphics card will be required.

Cloud based solutions are typically able to process larger files, as the processing is done online and does not depend on the local machine.

On larger projects, a dedicated 4D planning tool with scheduling functionality is recommended. However, on smaller projects it may be sufficient to represent each key project stage required for health and safety planning via a combination of layers and element properties, which are then filtered to form specific views of the model.

Contract/procurement implications

If BIM enabled time-based health and safety planning is a requirement of the project’s delivery team, it must be documented in the contract. This can be directly in the contract or as part of a BIM Execution Plan included as a contract document. It must be made clear in the contract with the designers that a BIM model is required for the purposes of time-based planning. It should also appear in the contractor’s contract.

The contract should specify responsibilities and milestones for the 4D model. It’s also important to clarify which party owns the model, such as the lead appointed design party during the design phase, the lead contractor, a third-party scheduling consultant, or the client.

In terms of procurement, additional scope may need to be determined with the party responsible for developing the 4D model.

Roles and responsibilities

| Client |

Specifies requirements and expectations for 4D modelling and provides appropriate resourcing for its use. |

| BIM authoring team |

Produces the model as part of their design deliverables. Often designers or specialist BIM modellers. |

| Scheduler | Works with the delivery teams to understand the key delivery timeframes and document them in scheduling software.

|

| Construction planner | Use spatial planning to identify areas where the delivery could pose health and safety risks. Considers all temporary works and construction traffic movements associated with delivering a project.

|

| Health and safety planner | Identifies potential health and safety hazards and suggests mitigating factors that can be tested in the model environment.

|

Training requirements

Model-based health and safety planning is a relatively new process and users will likely require training to get the most out of the method. It is easier to learn than traditional BIM tools and mostly requires users to become comfortable navigating a 3D model environment.

The software tools used for modelling health and safety elements often have an intuitive user interface, but may require a period of trial and error before users become fluent. It is recommended to allow a few weeks for users to test the software in a demo environment before working on live models.

Finding team members with video game experience and making them the project’s software champions is one way to promote this new form of planning.

Future directions

Time-based planning for health and safety has an encouraging future. The technique is advancing rapidly with graphics and interaction building on developments of video gaming technology.

Software tools are also becoming more capable. Current advances include systems with integrated artificial intelligence (AI) capability that allows them to automatically analyse models for potential hazards, such as exposed edges, trip hazards or confined spaces, and then suggest design actions to mitigate the risk.