Owner / Client | Model interaction for safety planning

Description

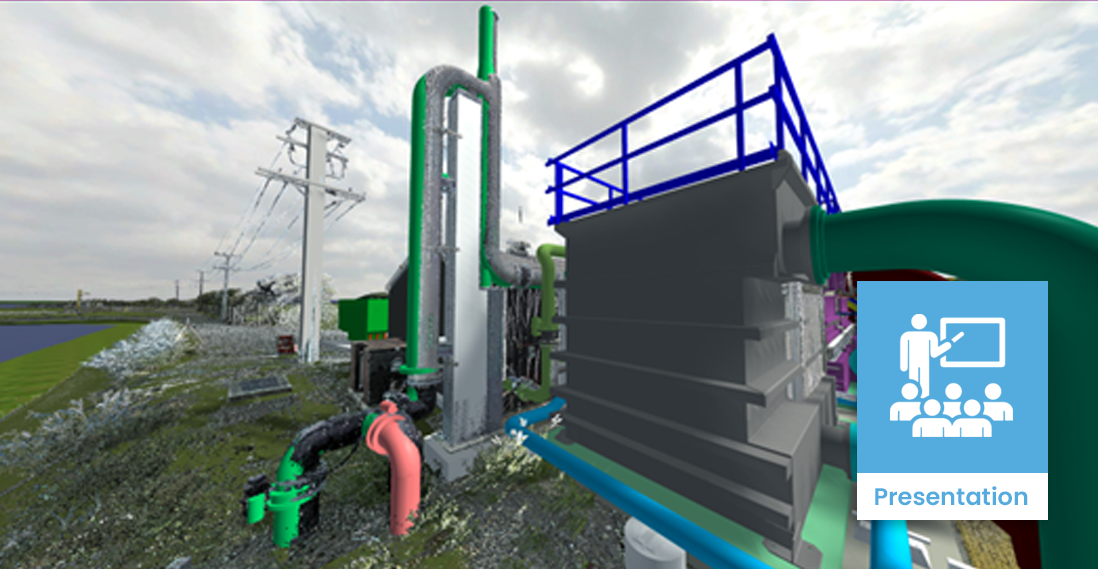

To be effective, safety planning must be a three-dimensional activity. However, traditional site planning is typically carried out in only two-dimensions.

BIM makes it possible to model a site in detail and use it to take into consideration a wider range of factors, without relying on individual experience. BIM models can bring a site to life and enable detailed site planning, well before it enters construction.

Planning using BIM models enables project members to interact with the site layout in an immersive environment with more than a traditional top-down schematic view. Interacting with the model from a first-person perspective gives the user the opportunity to explore all areas of the construction site and identify areas that are likely to need safety measures, such as barriers, scaffolding, signage, etc.

Using models for safety planning engages the wider project team and encourages more people to have input into the process of ensuring that the construction site will function in a safe manner.

Case studies

Uses and benefits for health and safety

Creates an engaging and immersive planning process that can identify safety risks that would be missed in a 2D plan-based review.

More informed decision-making when developing construction methodologies by having an accurate digital tool to visualise the project.

Better engage project teams and other stakeholders by enabling them to explore the design and construction site in a 3D environment.

Overcome language barriers and the inability to understand 2D plans by using visually immersive models that provide a more collaborative approach to safety planning.

Technology/techniques

A model viewer is an effective tool to identify areas that require safety interventions. It enables users to experience the model in a familiar way, giving them a first-person view and the ability to navigate with game-like functionality. By replicating view angles and personalising the experience, users will be more engaged as they can better imagine their future work scenario.

A potential issue should be marked and recorded in an issue management system so it can be assigned to someone to address, and tracked and traced to ensure it is complete. This also makes it easy for others to jump to points in the model that others have pointed out as a potential risk and add their own comments.

Model/data requirements

Essentially the aim is to create a digital version of the physical site. The more the model reflects reality , the better the planning session can be. To use more granular planning, the BIM models can be integrated with the project construction schedule in a 4D planning tool, or through a series of staged views that can be activated and deactivated in a standard model viewing tool.

When a BIM model contains correctly classified elements, specialist software can be used to analyse the model. These tools can help identify areas that may be potential safety hazards, such as falling hazards or low-hanging structures, or potential clashes, such as water pipes running directly above electrical rooms or comms rooms. Data structure becomes important when using these tools, as the computer must be able to interpret the building, which it cannot do with 3D geometry alone.

Hardware and software requirements

Hardware must have sufficient processing capability to smoothly view detailed 3D BIM models. Larger models will require a good-quality graphics card.

Alternatively, several web-based applications can process the model in the cloud and stream a view of the model content. This removes the need for local processing, however there may be some latency when navigating the model. A high-bandwidth internet connection can alleviate the lag.

As safety planning requires the communication of potential risks to a wider team to resolve, it’s crucial to use software that can create and track issues within the model.

Using a standard format to exchange issues, such as a BIM collaboration format, enables people to work in their preferred model authoring or viewing platform and create issues within a common database. The team can then see and comment on issues using their preferred software. This also avoids the need to procure a standard viewing platform for the entire team.

Contract/procurement implications

The client needs to document that BIM will be used for safety planning in the project contract or BIM execution plan. Designers and contractors also need to consider how they would undertake reviews using models. This doesn’t necessarily add to the scope and cost of the project, as it has the potential to streamline the review process.

Clients should engage early with their project teams and support the use of BIM. Alternatively, the client may require the project team to use the model as a central point of reference for all safety planning processes.

The client may ask the delivery team to provide them with a license for the viewing software being used for safety planning. They may also ask the team to provide regular reports about identified hazards and what safety measures have been put in place.

Roles and responsibilities

| Safety planner |

Coordinates with the BIM teams to ensure the models are federated and able to be used for planning. Also coordinates with those involved in safety planning across the project. |

| Head safety planner |

Manages the process as the project team marks up issues related to safety, and ensures issues are assigned to someone for further comment and resolution. ㅤ |

| Design team |

Ensures the design is correctly represented in the BIM model, rather than leaving it to modelling technicians to solve design issues.

ㅤ |

| Client representative | Receives regular reports about safety planning and any issues that the project team can’t resolve without further escalation. |

Training requirements

The project team must have sufficient training to navigate a 3D BIM model. They should be able to navigate in first-person, raise issues and move naturally around the model by themselves.

Future directions

As the BIM capability of design and construction teams continues to improve, projects will create higher quality 3D models that contain more detailed data. This will enable automated tools to check common safety rules.

As more projects use BIM to identify issues, automated tools will become more effective as the new data develops their algorithms. This leads to the possibility of tools that can monitor the design in the background and immediately alert the designer to potential safety issues.