Operator / Facilities Manager | Model visualisation for project communication

Description

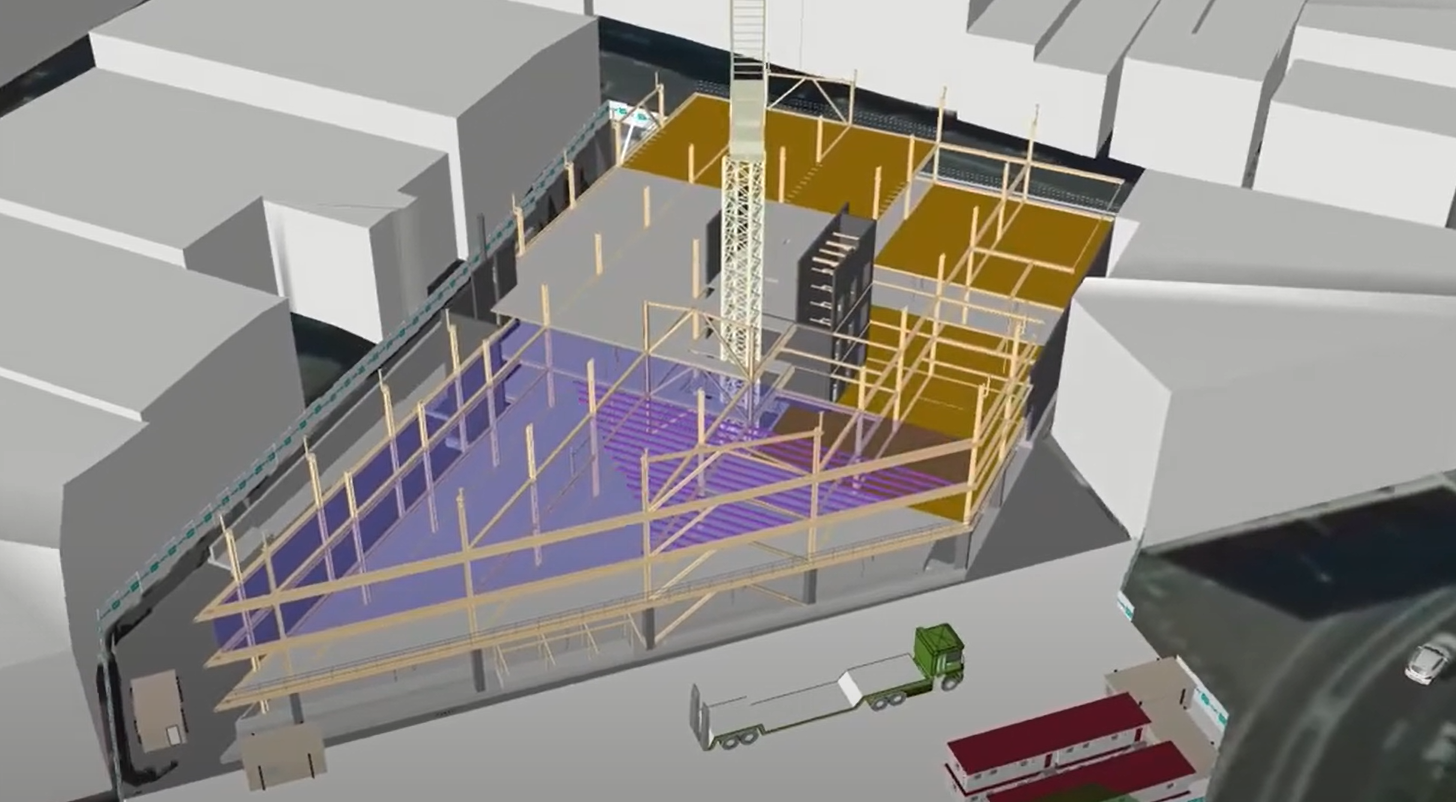

Building Information Model (BIM) visualisation involves navigating a virtual representation of the facility to access information and can be used to improve communication to support health and safety in facility operations.

Operators can gain a comprehensive understanding of the facility, including all systems, components and real-time operational data. Model visualisation can facilitate the gathering and sharing of health and safety information. Any planned refurbishment or maintenance work can use up-to-date information about the facility and its systems to communicate risk and safety processes, and ensure all operators have the information they need.

Case studies

Uses and benefits for health and safety

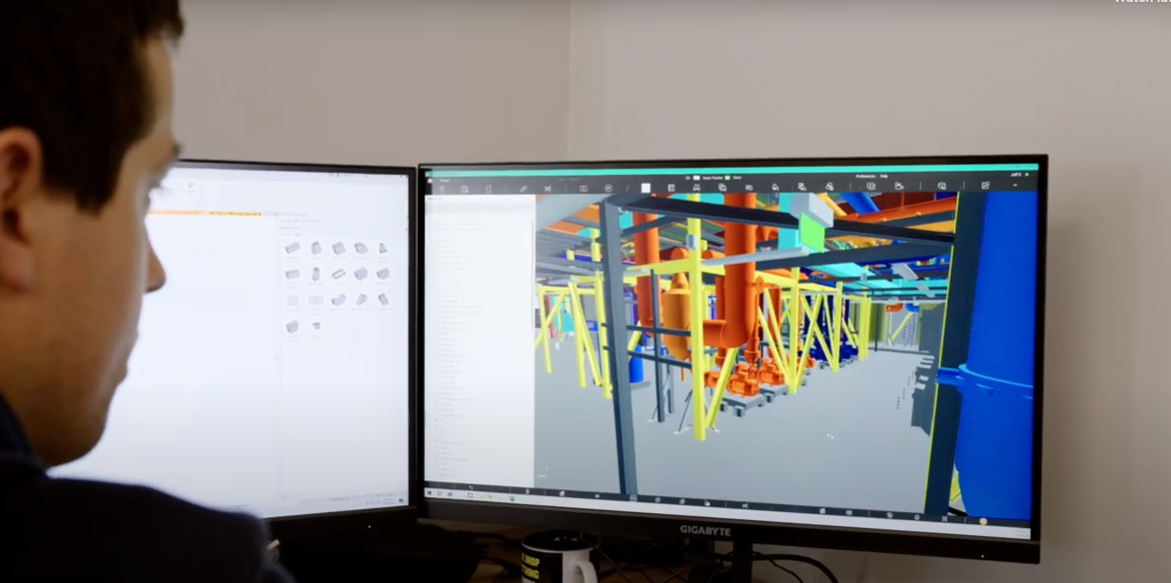

Improve hazard communication by providing easy access to the facility’s concealed systems, such as services behind walls or above a ceiling.

Improve site safety and hazard identification by enabling users to explore constrained spaces or other hazardous areas from within a safe virtual environment.

Other uses and benefits

Enable non-expert users to understand and explore the facility more easily than they could using 2D drawings.

Enable users to navigate the facility without interfering with the day-to-day operation of the actual facility.

Technology/techniques

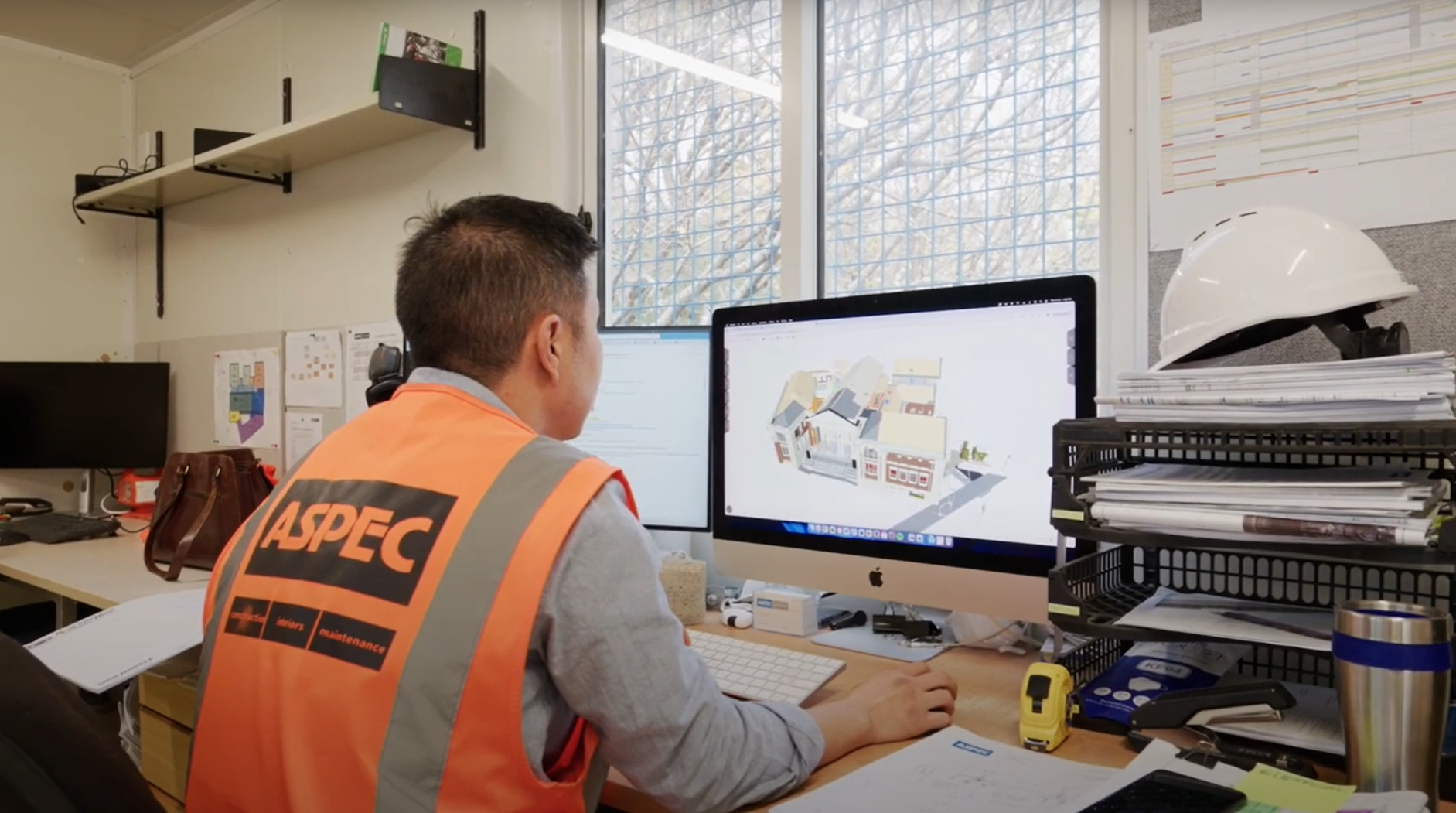

While a reasonable level of computing power is needed to create the BIM model, users can view the model using a range of different platforms. For instance, cloud-based BIM viewers on a mobile phone or tablet enable users to view information from the model using a mobile app.

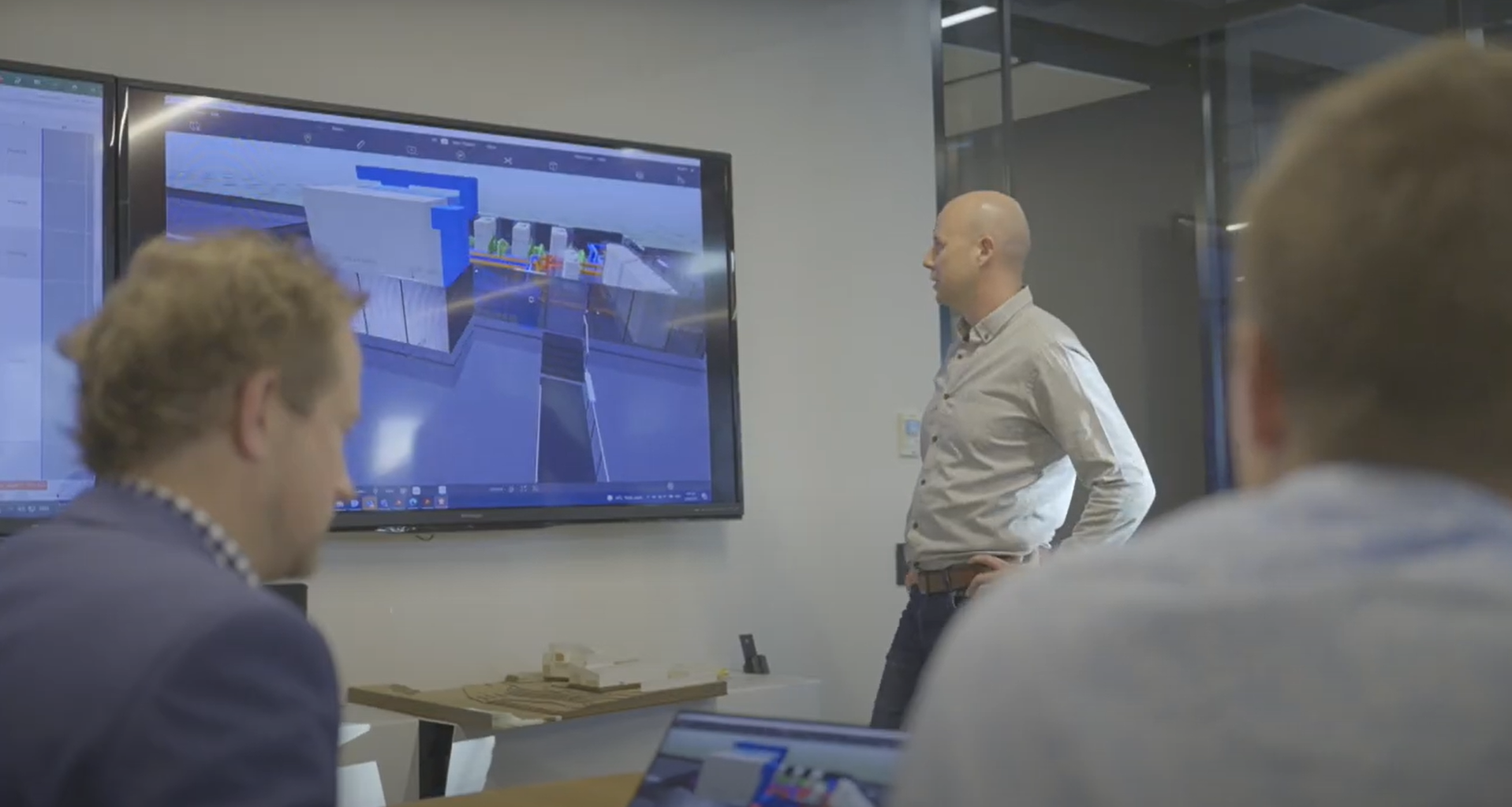

More complex visualisation may require specialised BIM software on a computer with a fast processor capable of running the software and a reasonably large monitor. For collaborative sessions, a large screen or projector may be useful.

Virtual and Augmented Reality (VR and AR) devices and platforms can be used to help operators gain better understanding of the facility. Most BIM software applications such as Autodesk’s Revit, Navisworks and BIM 360 provide rich visualisation features intended for communication. VR and AR technologies enable immersive experiences, where operators can interact with the model in a realistic virtual environment.

Model/data requirements

Using BIM to communicate safety information in the operations stage of a facility requires an up-to-date model, which includes accurate, as-built information, and complete information about any updates, renovations or modifications. The model should contain the historical record of changes and interventions to enable comparison and analysis.

Visualising changes to the facility, such as changes to materials, structural modifications or replaced equipment and products can help operators understand and the assess safety implications.

The model should be structured to provide independent access to specific building elements, for example by allowing walls and ceilings to be switched off so that hidden elements become visible. Specific rooms or elements should be viewable without having to engage with the entire model. This simplifies navigation and can prevent users from becoming overwhelmed with too much information.

Using an open standard data format helps to ensure compatibility with a range of visualisation devices, rather than limiting access to a proprietary system or software.

Hardware and software requirements

For general reporting and documentation, and to support visual queries, operators will require model authoring software, a computer capable of running the software, and a high-resolution monitor.

For specific reporting and documentation purposes, particularly when multiple collaborators are involved, a more dedicated system incorporating a large screen and projector may be useful. For more advanced collaborative reporting and documentation, particularly when it involves a complex structure or system, a VR headset or a mobile device with AR capability may also be required.

For general information sharing across the organisation, a touch screen station may be useful.

Contract/procurement implications

In contracts, stakeholders must clearly define the BIM deliverables, ensuring comprehensive data and accurate visualisation align with project goals. At the outset of a design and construction process, procurement strategies should emphasise long-term value and consider BIM’s use in operations and maintenance throughout the life of the facility. New projects should include an agreement on the method of communicating and visualising the facility information.

Procurement processes may need to be adapted to prioritise vendors with BIM expertise, fostering collaboration and data integration. Contracts should establish data ownership, access, and update protocols to facilitate seamless facility management.

A well-defined BIM strategy in contracts and procurement enhances collaboration, minimises disputes, and optimises facility performance throughout its lifecycle.

Roles and responsibilities

| Facility manager | Oversees the use of BIM visualisation in daily operations, ensures the model is used effectively for safety communications and decision-making. |

| BIM manager | Responsible for maintaining and updating the BIM model, ensuring it accurately reflects the current state of the facility and contains relevant safety information. |

| Health and safety officer | Uses the BIM model to identify potential hazards, plan safety improvements, and communicate safety procedures to staff. |

| Maintenance team | Uses BIM visualisations for planning and executing maintenance tasks safely, updating the model with as-built information after work completion. |

Training requirements

In addition to proficiency in BIM software, an understanding of facility management concepts is useful as it informs operational processes and decisions that model will need to support.

The operator should be proficient with BIM software and be trained in 3D modelling, data integration and visualisation techniques. An understanding of facility management concepts is also useful as it informs operational processes and decisions that model will need to support.

Training on advanced visualisation techniques, such as AR and VR, may be necessary.

Future directions

Immersive technologies, such as VR and AR, to guide on-site maintenance are becoming more widely accepted. The growing availability of continuous data feeds makes it possible to carry out real-time performance monitoring and visualisation, and facilitate communication among stakeholders.

Wearable devices may become a common means to communicate information.