Designer | Simulation for hazard identification

Description

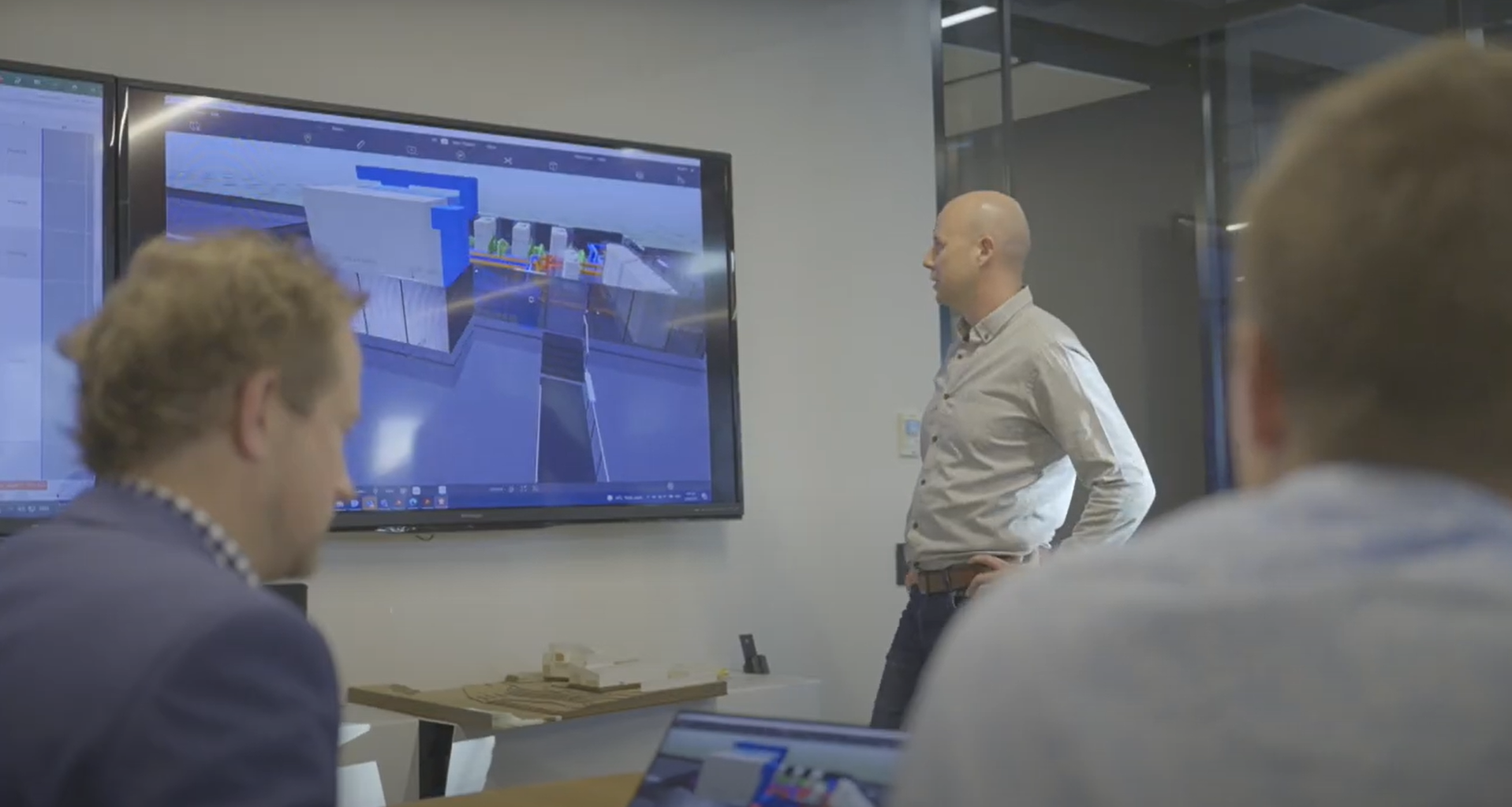

BIM models and associated data can be used in simulations to visualise and quantify potential hazards during the design stage. These simulations incorporate dynamic elements often overlooked in static models, such as the movement of vehicles, equipment operation, and people flow. By allowing virtual risk assessment before construction begins, these tools significantly improve site safety and efficiency.

Examples of simulations include traffic flow management, space utilisation conflicts, evacuation time modelling, fire and smoke spread analysis, crane operations, and temporary works. These techniques enable design teams to make informed decisions about site layout, construction sequencing, and safety measures, leading to safer designs, more efficient processes, and reduced accident risks.

Case studies

Uses and benefits for health and safety

- Better understand known hazards that cannot be easily expressed or understood in a static sense (that is, by using drawings and models), such as movements on site.

- space

- Improve understanding of design outcomes relating to time and movement and the risks they could present. Identify hazards and reduce risks not easily visualised on paper.

- space

- Improve safety by testing a range of potential scenarios and optimising design solutions.

- space

- Assure stakeholders that, as much possible, harm has been identified and designed out.

Technology/techniques

A range of simulation tools and techniques are available for hazard identification in construction during the design stage which each provide their own area of application. 4D BIM simulations simulate the construction process by integrating 3D models with project schedules to visualise construction sequences and identify potential temporal and spatial conflicts. Virtual Reality (VR) and Augmented Reality (AR) technologies enable immersive site walkthroughs, allowing designers to experience and evaluate spaces from a safety perspective before construction begins.

More specialised simulations include Computational Fluid Dynamics (CFD) which can assess air quality, ventilation, and the spread of hazardous substances in enclosed spaces. Finite Element Analysis (FEA) is used to simulate structural behaviour under various loads and conditions, helping to identify potential failure points. Agent-based modelling can simulate worker movements and interactions on site, highlighting areas of congestion or potential collisions. Additionally, a range of statistical simulations can be used to analyse the probability and impact of risk scenarios, which can be used to support a hazard identification exercise.

Model/data requirements

Geometry and scenario specifics are needed for hazard identification. Simulation tools will have their own input requirements and the format should be established early to ensure that the BIM models use a compatible format.

The realism of the BIM models (textures etc) is not as important as the accuracy of the geometry, time and movement relating to the scenario. For this reason, design metadata likely won’t be as prominent, unless there is staging information in the model which might drive some of the simulations.

Hardware and software requirements

Creating a simulation is a specialist task and only the person generating and running the model requires a high-specification computer. The specific software required will be determined by the simulation specialist, depending on the focus or goals of the simulation exercise.

Outputs from a simulation can generally be exported to a video or other format, for non-specialists to view and use to identify hazards.

Contract/procurement implications

Simulations often requires using a specialist consultant, so falls outside of the standard design process. The cost and availability of the consultant needs to be allowed for in the contractual arrangements.

The scope and extent of simulations should be clearly defined. Although they aid design, simulation is unlikely to identify all possible hazards, as the scenarios are based on specific foreseeable situations.

Roles and responsibilities

| Simulation specialist |

Develops scenarios and analyses the results using BIM models and specialised software. |

| Design team |

Creates the design and models. |

| Stakeholders/Client |

Work with modellers and simulation specialists to outline potential scenarios, including objects, personnel and activities on site, so they can be recreated in a virtual sense. |

Training requirements

A simulation specialist requires extensive training, but they’re likely to have completed this before the project begins. All other roles need no additional training to identify hazards using a simulation.

Future directions

While the BIM model used in a simulation can be developed by the design BIM team, the simulation process is traditionally the domain of specialists, requiring particular expertise to set up and interpret.

Game engines and virtual reality environments make it easier for non-specialists to visualise and interact with digital representations of a project, although working with these tools requires software development skills. New tools, such as Urban Circus, reduce the expertise needed to provide these visualisations and active scenarios.

Artificial intelligence developments include the use of predictive models to review and identify potential hazards within a building model. Prototypes are already available of this type of system, and the rapid advance of AI makes it likely that they will be widely available in the near future.