Contractor / Subcontractor | Reality capture for inspection and monitoring

Description

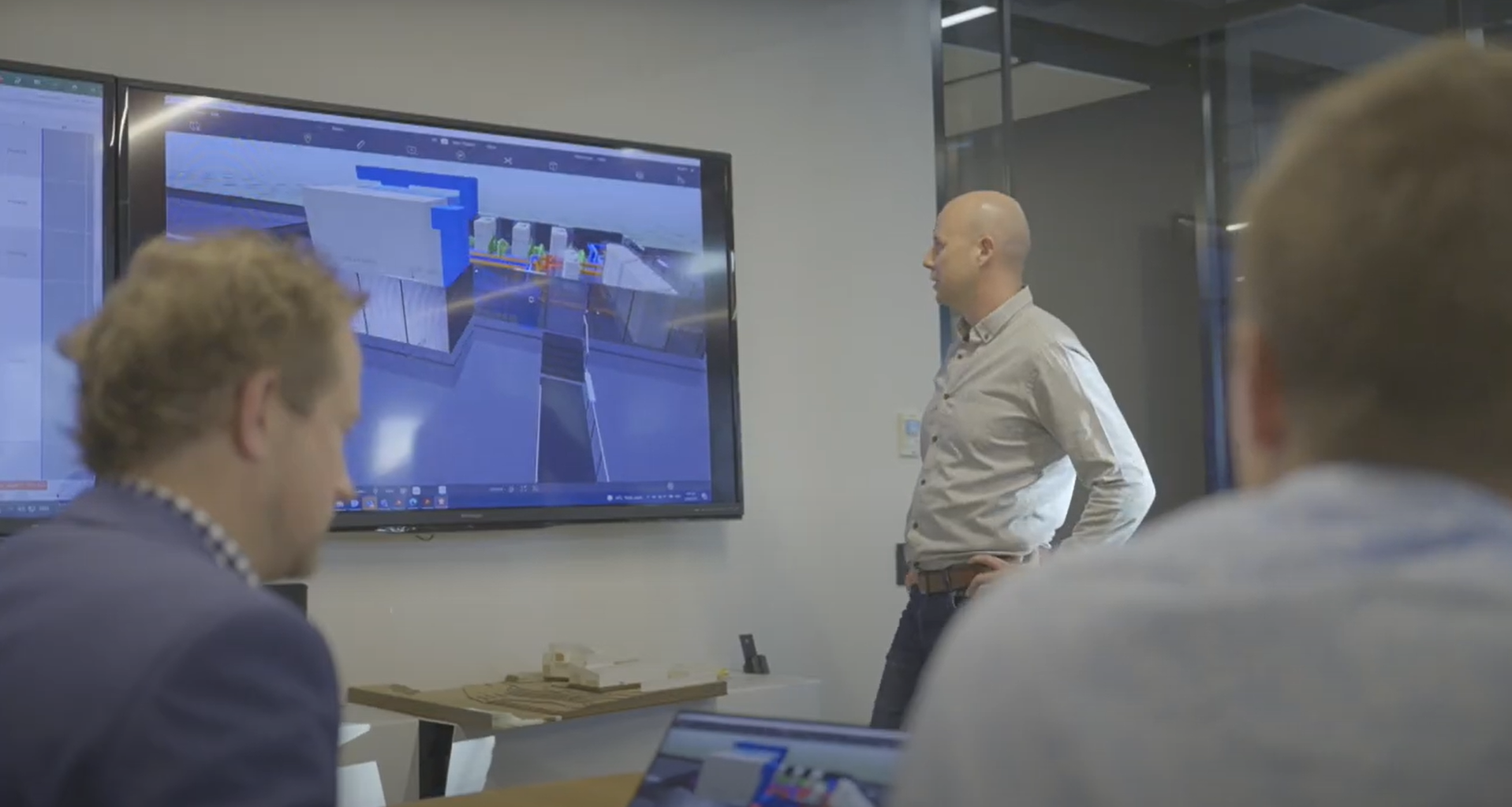

Reality capture uses drones and other survey methods to perform inspection and monitoring during construction.

Because it can operate remotely, reality capture is a great tool to record conditions in hazardous environments, where it’s necessary to reduce the risks to humans but they cannot be otherwise mitigated.

Examples include sites with toxic fumes or dangerously unstable terrain. The technique successfully surveyed the Christchurch Cathedral after the earthquakes in 2010 and land slips in Hawkes Bay after the 2023 floods.

Case studies

Uses and benefits for health and safety

Minimise or even eliminate the risk to people by remotely monitoring and inspecting the site.

Improve the identification of site features and hazards by enabling multiple team members to remotely review the captured data.

Improve the quality and accuracy of the capture data, and thus improving the inspection and monitoring focus of hazards, by using drones and other aerial vehicles that can access angles not available to humans.

Technology/techniques

Most reality capture techniques use point cloud, photogrammetry or lidar data to record site conditions. This requires a capture device, such as a laser scanner or camera.

Under normal circumstances, a person carries the device around the site to build up a complete picture of the surrounding conditions. This isn’t possible in a hazardous environment, so the capture device is mounted on a robot or drone which carries the device instead.

Model/data requirements

Reality capture doesn’t require a BIM model, but it’s often useful to combine the two. If this is a project objective, make sure to also:

- space

- record geolocation data

- space

- record the time and method of capture (data may become unreliable in the future)

- space

- specify an output format (ensures authoring/design tools can work with the data)

Hardware and software requirements

Reality capture requires a capture device and software to process it into a usable 3D model.

The capture device usually scans and records its surroundings using point cloud, lidar or photogrammetry data. When operating in a hazardous environment, a mobile capture apparatus is also required to carry the device, such as a drone, rover or robot.

Each scanner manufacturer provides its own proprietary processing software. The project team will need a high-powered computer to run the software and process the raw data into a usable format. The team can view the data using the processing software and export it to various formats for others to use.

Contract/procurement implications

Reality capture does not typically influence the contract between the client and contractor. If anything, it is used to reduce risk for both parties.

While the cost of capture devices and setup may be seen as an over-and-above cost, this will likely balance itself out by reducing the need for people to visit the site, and reducing the risk of harm if they did.

Roles and responsibilities

Using reality capture for site investigation and monitoring involves several roles:

| Surveyor/Operator |

Captures the site conditions. This is the only person who needs to get relatively close to the site. |

| Design/Contractor team |

Uses the captured site conditions to make informed decisions about the project and safety of personnel. |

| Client stakeholders |

Responsible for all activity on site. |

Training requirements

Most of the training related to data capture should be part of the surveyor’s day-to-day activities, although they may require an operating license if they fly a drone.

Teams which are unfamiliar with the project’s capture techniques and data formats should receive sufficient training. Alternatively, the project could specify outputs the team has used before.

Future directions

The industry trend of using reality capture to remotely inspect and monitor sites – both hazardous and non-hazardous – will continue to grow in the coming years.

Improvements in machine learning, robotics and remote autonomous systems will lessen the need for human control during the scanning process. The speed, range, agility and cost-effectiveness of drones in particular will mean they can scan a site faster, more frequently and in greater detail then a human-carried device.