Helix Global: Prefabricated housing using BIM

Summary

“BIM for us is critical, it allows us to plan well in advance of the tasks for what we’re doing, it allows us to sequence tasks in a manner that’s safe.”

Reegan Lawton, Helix Global CEO

Helix Global is pioneering New Zealand’s first fully off-site manufactured residential home. By leveraging Building Information Modelling (BIM) technology, the company has been able to address the unique challenges associated with prefabricated construction, transportation, and on-site assembly. The use of BIM has enabled Helix Global to enhance safety throughout the entire process, from factory manufacturing to final installation.

Background

Helix Global is a Christchurch-based design and construction company. According to CEO Reegan Lawton, they are currently building New Zealand’s first “fully off-site manufactured residential home.” This innovative project involves building the house in a factory setting, deconstructing it into modular pieces for transport, and then reassembling it on-site. The project presents unique challenges in terms of manufacturing, logistics, and safety considerations across all phases of construction and assembly.

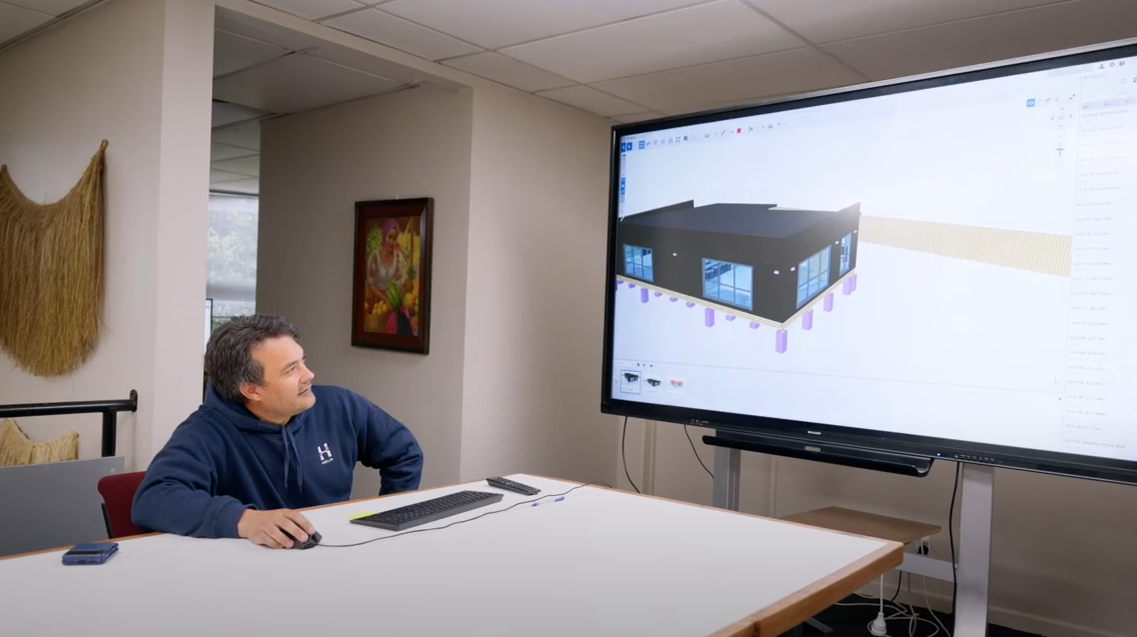

Video

Approach

Helix Global has been using BIM technology in design since the late 1990s, and it plays a central role in the design and construction of their prefabricated home project. The BIM model allows the team to plan and visualise tasks well in advance, identifying potential challenges and safety risks before they occur. This approach helps them to sequence tasks in a manner that prioritises safety, particularly important given the space constraints in their indoor facility.

One specific example of BIM’s application was in solving the challenge of transporting the prefabricated modules. Initially, the team considered using open-top containers, but the BIM model revealed significant safety risks associated with lifting heavy modules over 3.5 meters high. This insight led to the development of custom containers that can be loaded and unloaded at ground level, substantially reducing the risk of accidents during transport and assembly.

Additionally, the BIM model was used to manage the factory layout and workflow. By planning the movement of materials and workers through the factory, Helix Global was able to design a safe and efficient workspace to minimise the risk of collisions, trips, and other workplace hazards.

Outcomes and benefits

Health and safety benefits

- Improved work environment: The factory setting provides a stable, clean, and controlled environment, eliminating many hazards associated with outdoor construction such as adverse weather conditions, uneven surfaces, and open trenches.

- Enhanced risk mitigation: BIM allows for early identification and mitigation of health and safety risks, enabling the team to isolate or eliminate hazards before they become issues on the factory floor or construction site.

- Safer transportation solutions: By using BIM to visualise and plan the transportation process, Helix Global developed a safer method for moving prefabricated modules, significantly reducing the risk of accidents during loading, transport, and unloading.

- Efficient resource planning: The prefabrication process, guided by the BIM model, allows for more effective planning of both labour and materials, reducing on-site risks associated with resource shortages or overallocation.

Other benefits

- Improved coordination: BIM facilitates better communication and coordination among team members, ensuring everyone understands the project sequence and safety protocols.

- Increased efficiency: The ability to plan and visualise the entire construction process in advance leads to more efficient operations, reducing time on-site and associated risks.

Lessons learnt

BIM works beyond the building

BIM’s value extends beyond just modelling the building itself. Helix Global applied BIM to their factory layout and transportation logistics and identified opportunities for safety improvements and efficiency gains. On traditional projects, the same applies, with temporary and enabling works also benefiting from planning in the model.

Off-site manufacture enhances safety

By moving the majority of construction work into a controlled factory environment, the Helix Global team has eliminated many common site-based hazards such as working at height, exposure to weather, and uneven ground conditions. The BIM model allows for precise planning of the factory layout and workflows, further reducing the risk of accidents. This approach not only improves safety during the manufacturing phase but also minimises the time workers spend on the final construction site, where risks are typically higher.

Invest for the long-term

Implementing BIM is an ongoing process of learning and improvement, that is not limited to one scale or purpose within the industry. Helix Global’s use of BIM over more than 30 years, from structural design to modern prefabricated housing, highlights the long-term value of investing in BIM technology and expertise.