ACC Ōtepoti: Use of a 4D animation for planning

Summary

“Being able to see it as a team together in three dimensions in front of you allows us to perceive risk in a way that’s just not possible from a set of 2D drawings.” Matt Soppit, Project Manager, Naylor Love

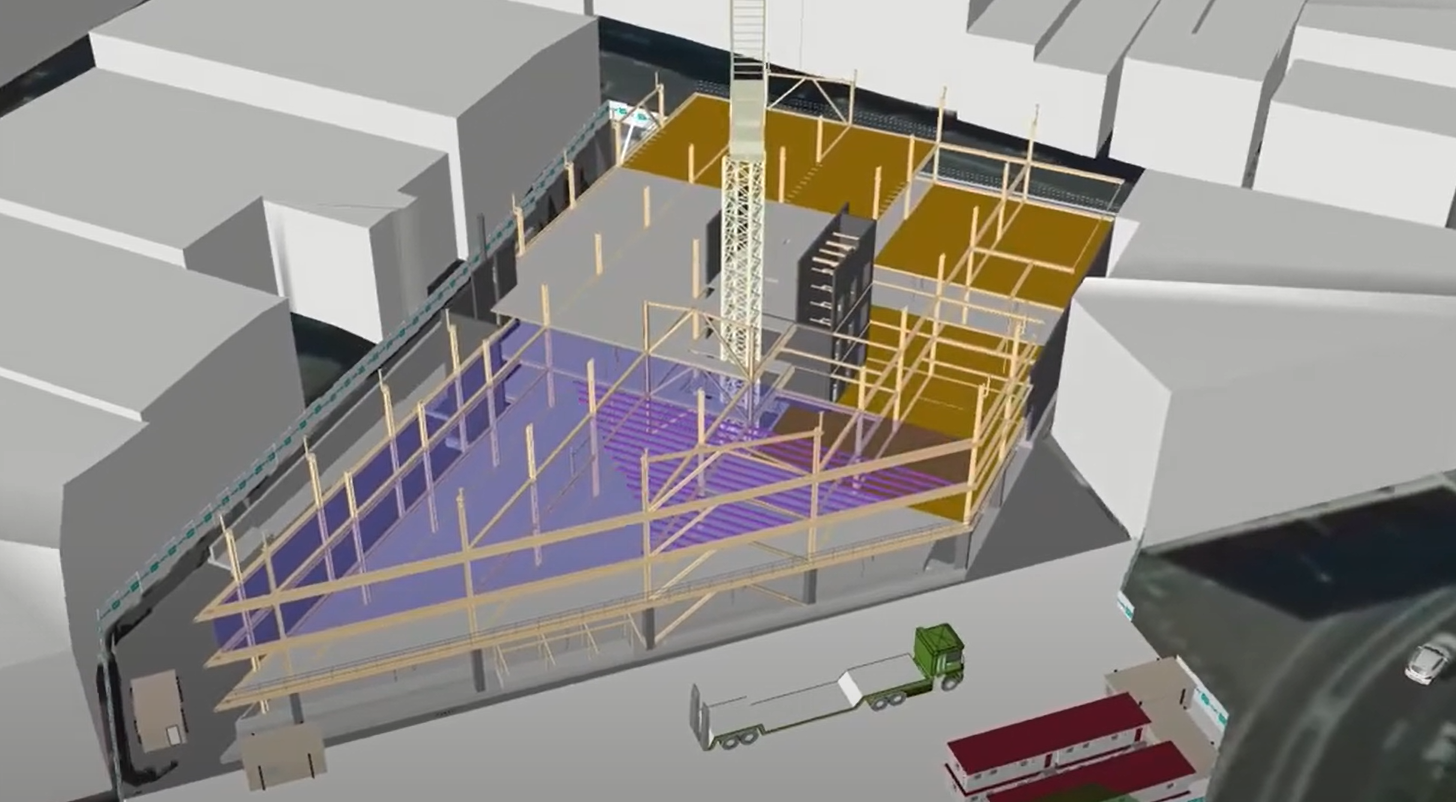

The ACC Ōtepoti project team used 4D BIM technology to support their construction safety planning, particularly focusing on structural steel and floor slab installation. By creating an animation of the BIM model visualisation against the project timeline, the team could identify and address potential safety risks months before construction began. This approach helped to identify key problems with the planned sequence of works, enabled better coordination between different trades, and helped create safer working conditions for everyone involved in the construction process.

Background

The ACC Ōtepoti project is a new office building for the Accident Compensation Corporation (ACC) in Dunedin, New Zealand. The project is a joint venture between Ngāi Tahu Property and ACC.

The building area is 8,000 square meters over four storeys. The project is located between Dowling Street and Queens Gardens, a site with historical and cultural significance for Dunedin and Ngāi Tahu. The project has encountered a number of challenges, such as complex site conditions (including archaeological finds and neighbouring historic buildings), seismic requirements, a tight schedule, and the COVID-19 pandemic.

The main stakeholders of the project include Ngāi Tahu Property, ACC, RCP (the project manager), Warren and Mahoney (architect), Naylor Love (main contractor), Aukaha (cultural advisor), and various consultants and subcontractors.

Video

Approach

The project team faced some sequencing challenges in determining how the building structural steel and installation of floor slabs were to be carried out. A third-party BIM specialist was tasked with creating a 4D visualisation of the construction process, specifically focusing on this stage of the project. The 4D approach helped the project team to identify several critical safety considerations, such as managing fall protection and dropped object risks across multiple levels, as some areas would have completed floor slabs on levels 1 and 2 while structural steel work continued four storeys above. The team used the visualisation to work through multiple coordination sessions between architects, mechanical services contractors, and other stakeholders, to develop safe work sequences months in advance of actual construction, and several changes were made from the version first modelled, to improve the process.

The 4D visualisation proved particularly valuable for complex installations. For example, it was evident that the plant deck installation needed further design as it was unable to be built as originally planned. By October, the team had already conducted three to four sessions planning work that wouldn’t begin until May of the following year. This advance planning allowed them to develop the design and construction methodology, determine logical sequences, coordinate between different trades, and reduce the time workers would need to spend working at height. The visual nature of the 4D model provided a shared understanding that helped team members see not just what they were building, but the optimal sequence of installation considering safety implications.

Outcomes and benefits

- Enhanced safety planning: The 4D visualisation helped the team to identify potential hazards related to working at height and falling objects across multiple levels of construction. This allowed for the development of comprehensive safety strategies before work began.

- Improved trade coordination: The ability to see the construction sequence in advance helped different trades understand their interdependencies and plan work to minimise conflicts and safety risks. This was particularly valuable for coordinating structural steel, flooring, and services installation.

- Reduced risk through advanced planning: By planning complex installations months in advance, the team could eliminate the need for workers to “solve problems on the fly”, which often puts them at greater risk due to divided attention and unexpected situations.

Lessons learnt

Outsourcing can bring in skills and resources to support the team

While internal teams may understand the project context better, external specialists can provide advanced technical expertise and dedicated resources that would be difficult to maintain in-house. Using an external provider for this part of the project generated a high-quality 4D visualisation for critical sequences, while avoiding the overhead of developing and maintaining these capabilities in-house.

Focus on high-impact areas or processes

A 4D animation doesn’t need to cover the whole project, but can be used selectively to focus on particularly challenging elements. Projects often don’t have the resources to develop and update 4D models to reflect ongoing changes in the design, construction methodology and programme, but targeting complex interfaces and high-risk sequences can provide maximum value with a lower modelling overhead. The team found that a single 4D model of the structural erection process was enough for them to gain the key benefits of 4D planning without too much cost or effort.

Efficiency and safety are linked

The most efficient construction sequence often proves to be the safest, as it reduces rework and allows workers to focus on executing well-planned tasks, rather than solving unexpected problems while in potentially hazardous situations.