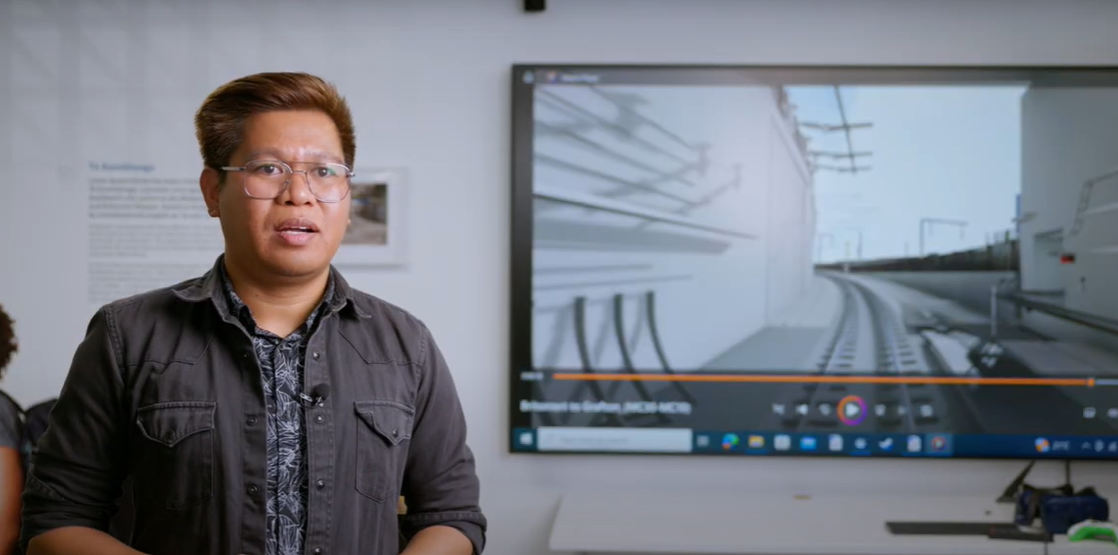

City Rail Link: BIM simulation for driver training

Summary

For the Central Rail Link project, the BIM model is used as the basis for a virtual reality fly-through to educate train drivers and communicate project progress to the public. This innovative approach allows drivers to experience and prepare for potential hazards they may encounter during construction, enhancing safety and awareness. The 3D model is updated quarterly to reflect current site conditions, including temporary works, machinery, and permanent installations.

Background

The Central Rail Link (CRL) project is the largest transport infrastructure project New Zealand has ever built. It features two 3.45-kilometre-long tunnels which have been built up to 42 metres below the Auckland city centre. The project faces challenges typical of large-scale underground construction, including complex work environments, diverse workforce, and critical safety requirements.

CRL is funded jointly by the Crown (NZ Government) and Auckland Council. Design and construction on the project have been carried out by the Link Alliance. This consists of City Rail Link Ltd (CRLL), Vinci Construction Grands Projects S.A.S, Downer NZ Ltd, Soletanche Bachy International NZ Limited, WSP New Zealand Limited, AECOM New Zealand Limited , Tonkin + Taylor Limited.

Video

Approach

The project team used BIM to create a detailed 3D fly-through model of the rail route which incorporates temporary works, machinery, and plant at their actual locations along the route. The virtual fly-through also includes information on permanent works as they are completed. This model is used with driver simulators to help drivers to familiarise themselves with critical safety information in the context of the changing construction environment. A key feature of this approach is the integration of signal locations within the model. Additionally, the model highlights temporary structures like hoardings, which can significantly impact visibility and safety considerations for drivers. The model is updated quarterly to reflect the current state of construction.

Outcomes and benefits

Health and safety benefits

- Enhanced hazard awareness: Drivers can visualise and prepare for potential hazards before encountering them in real-life situations, improving their ability to respond safely.

- Incorporation of construction and maintenance considerations:Visualisation using the BIM model enabled understanding of construction processes and access requirements for future equipment maintenance and repair work.

- Improved communication:The virtual model facilitates better communication between train drivers and the construction team, allowing for more effective safety planning and hazard mitigation.

- Proactive safety improvements:Drivers can provide feedback on the model, suggesting improvements to lines of sight or identifying other safety concerns, which can be addressed before they become real-world issues.

Other benefits

- Public communication: The virtual fly-through serves as an effective tool for communicating project progress and changes to the public, enhancing transparency and understanding.

Lessons learnt

Consider new training environments that VR makes possible

VR training provides a safe and effective way for participants to experience and prepare for potential hazards without risking real-world consequences. In this case, drivers could encounter multiple construction stages and their impacts on routes – experiences that would be impractical or impossible to provide through traditional on-site training.

Encourage user engagement and input

Because the training is carried out in a safe, accessible and available environment, participants in the safety process can provide their feedback immediately in response to the experience. In this case study, drivers experiencing the virtual model were able to contribute valuable insights and suggest adjustments to the project overall which improved project safety.

Manage the trade-off between frequent updates and model creation costs

To balance the need for up-to-date information against the resources required to create new flythroughs or simulations, it’s important to agree on what information is essential to the flythroughs. In the CRL case, updates were made quarterly to reflect key changes happening along the rail lines.

Use more information sources

The construction BIM model may need to be augmented to provide a richer experience for users of a safety simulation. For this project, combining information on temporary works, permanent installations, and critical safety elements like signal locations in one model provided a comprehensive training tool.