Operator / Facilities Manager | Model visualisation for planning

Description

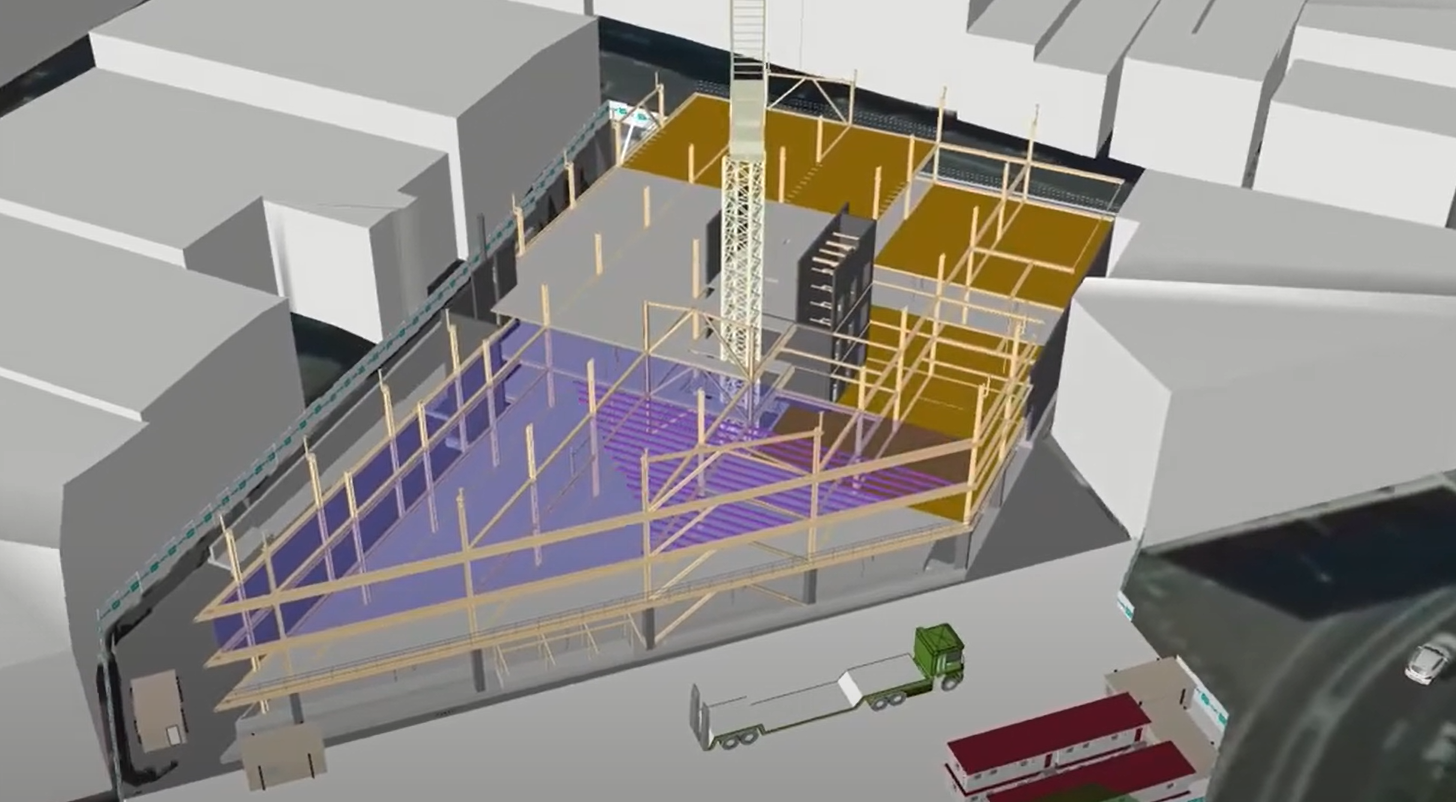

Planning for safe operations and maintenance can be greatly enhanced by a 3D model, especially on sites with active risks, such as manufacturing facilities or sites which operate 24 hours per day.

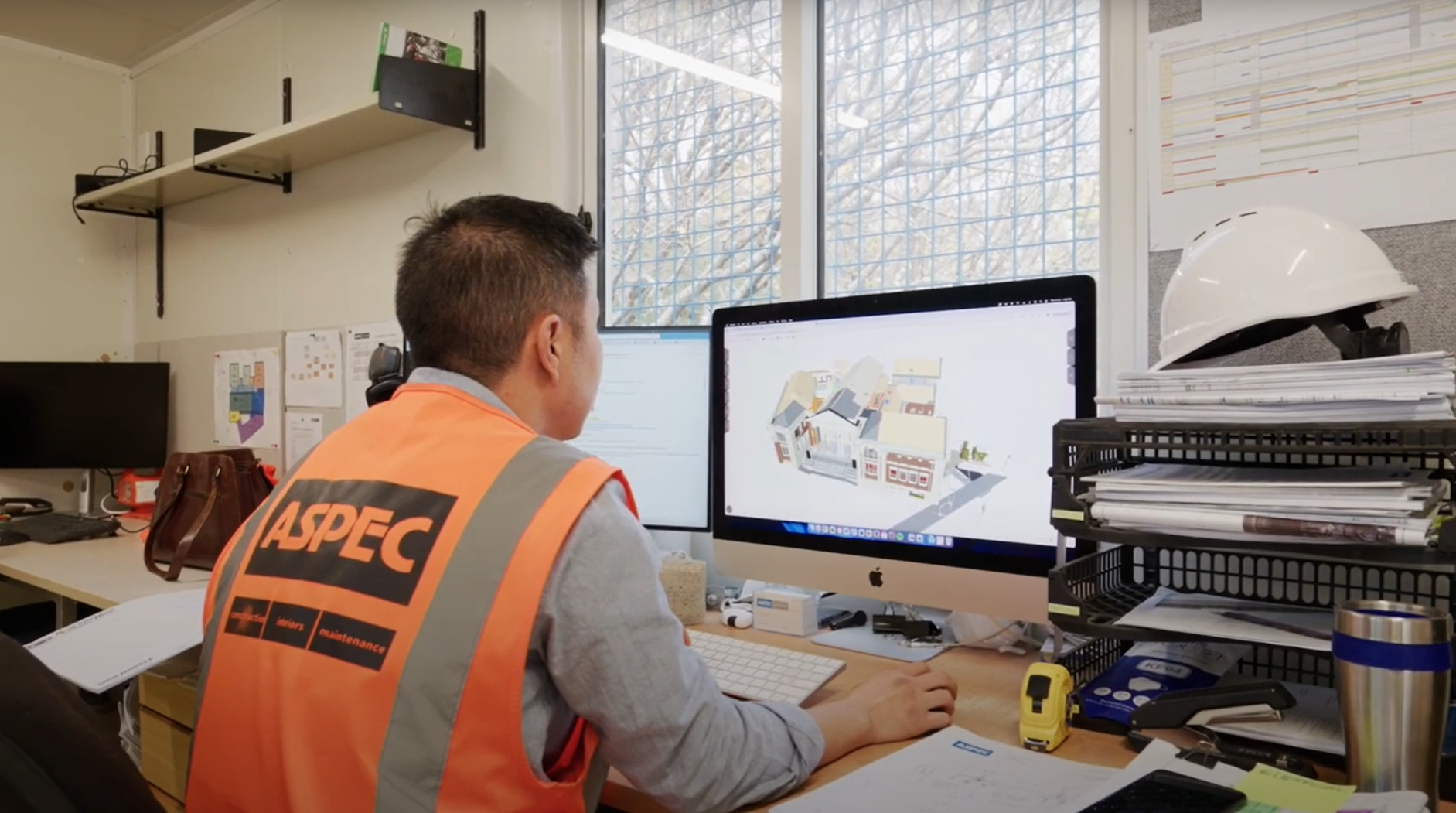

One way to do this is with a digital representation of the work. When used during the planning process, model visualisation can reduce the risk of anything going wrong on site. Teams can review and visualise their work environment and the task taking place.

Case studies

Uses and benefits for health and safety

Improves safety for operators and facilities managers by enabling them to plan and make decisions using the model rather than entering a live environment.

Improves safety for workers by clarifying methods, resources and equipment before they enter a hazardous area.

Minimises exposure to hazards by planning tasks in a virtual environment before entering the live environment.

Other uses and benefits

Reduces the time that on-site activities have to be halted, which may reduce operational risk.

Technology/techniques

Using BIM visualisation to plan for health and safety in the operations stage relies on the availability of models to visualise existing conditions.

In the event that additional modelling is required, for example to update the model on maintenance or construction works, it’s likely that consultants or a specialist BIM modelling team will facilitate the work.

Model/data requirements

For model visualisation to be successful in operating a facility, clients must clearly identify their expectation that a suitable, as-built BIM model is a project deliverable. Clients are often unaware of the benefits of using a model after the design stage and opt to reduce costs. This hinders the use of models in operations and should be avoided.

For owners who haven’t specified model deliverables, a substantial scan-to-BIM project would be needed. This approach uses reality capture to create an as-built model, which may be a massive undertaking, depending on the scale of the facility.

Hardware and software requirements

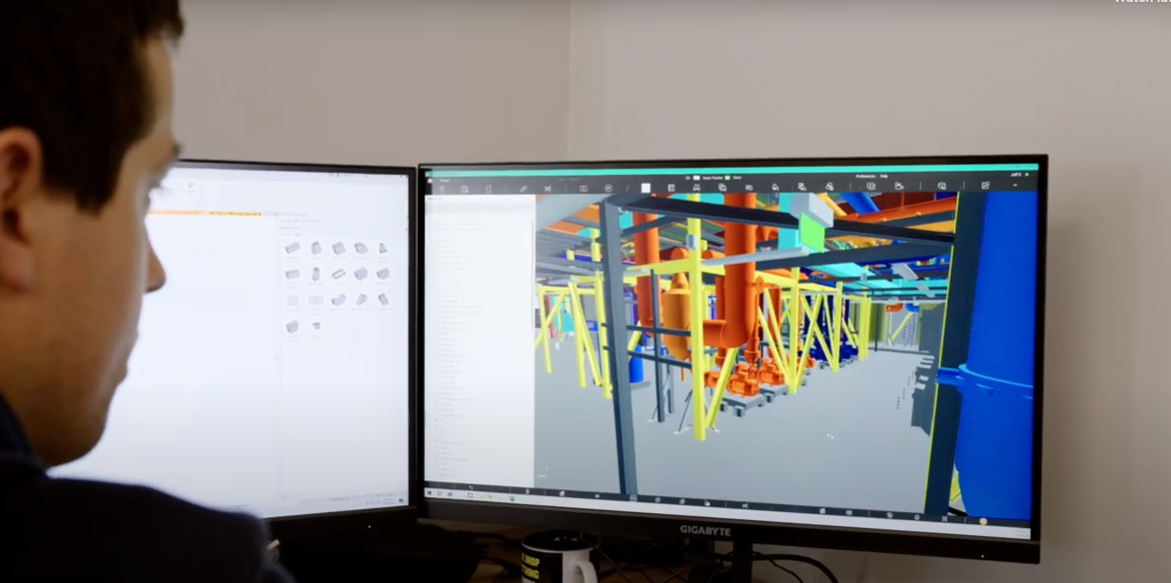

If the client intends to outsource model authoring to consultants, project staff will only require visualisation software. In most cases, a tool such as Navisworks or Revizto is sufficient.

Visualisation software doesn’t typically require a high performance machine. Mobile phones or tablets may also be used with cloud-based viewers.

If teams choose to use virtual reality (VR) or virtual rooms to review information, they may require more capable hardware and software. The client needs to identify this use early, so the BIM model includes a VR model.

Contract/procurement implications

For BIM to be successful during an asset’s operational period, all project participants must agree to digital deliverables at the project’s inception. This needs to be clearly written into contracts long before the asset is constructed and should detail what information is required and when it should be delivered. These deliverables need to be auditable with a clear agreement on acceptance.

Roles and responsibilities

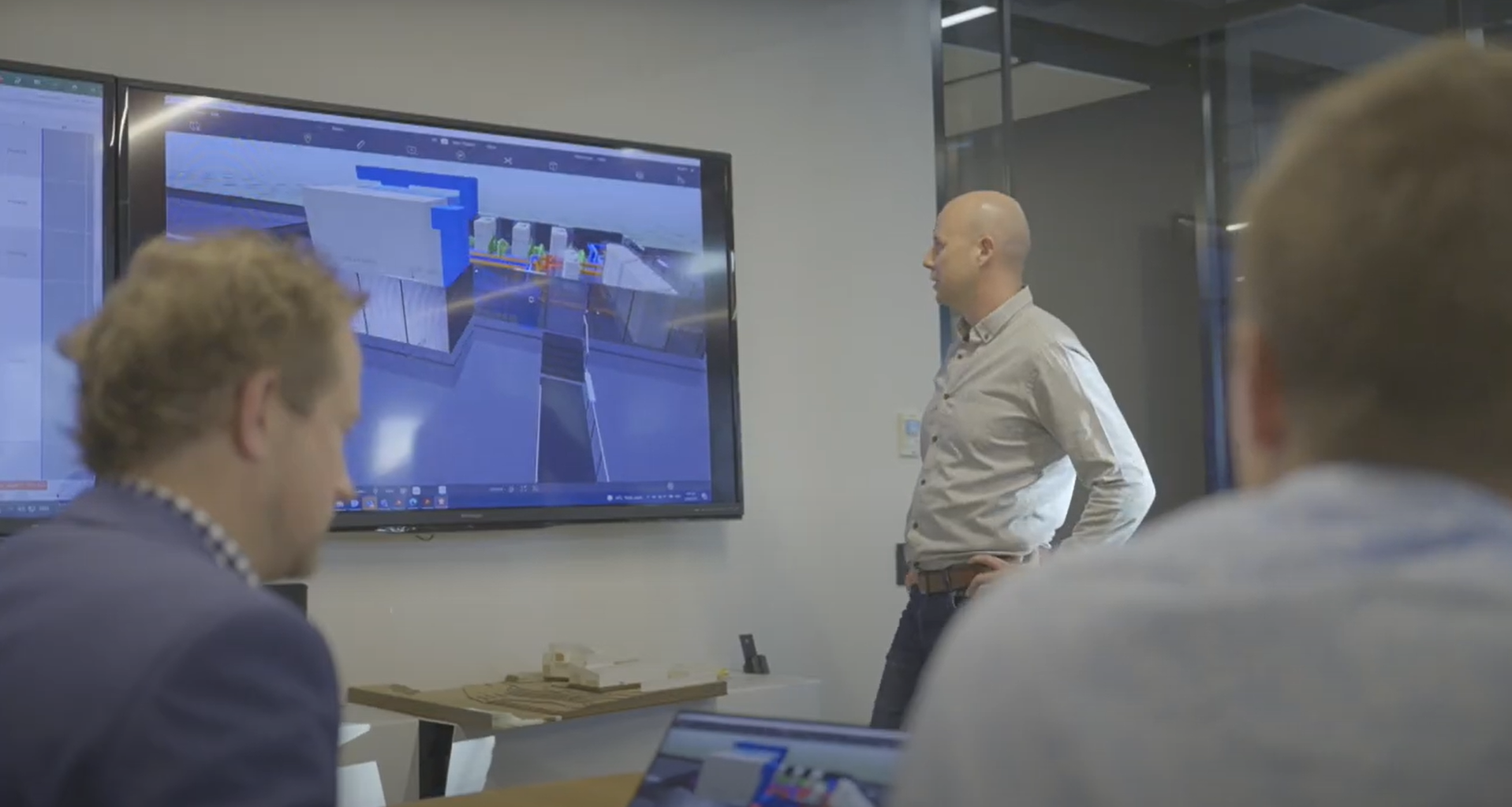

| Consultant | Models any information required to successfully plan the outcomes of the tasks at hand. On specialist sites, such as an oil rig, the client may choose to have someone in-house who understands the site and can quickly mock up the potential changes and activities. |

| Operator | Active on site and best-placed to understand the constraints and what can be achieved. |

| Client / owner | Drives better ways of working, with support from management. |

Training requirements

Once the project selects software visualisation tool, staff members who will participate should be trained on how to use it. As this is not their day-to-day activity, they may need additional refresher training from time to time.

Future directions

At present, it’s primarily asset owners in complex environments who use model visualisation to plan safe operations.

However, the technique has great potential to make smaller assets safer as well. Smaller building owners could begin with relatively minor tasks, such as accessing fan coil units in ceilings, which can be done more efficiently and safely when the maintenance team understands the site constraints before they arrive on site.

The more clients become aware of these benefits, the more it will influence change across the industry.