Operator / Facilities Manager | Reality capture for reporting and documentation

Description

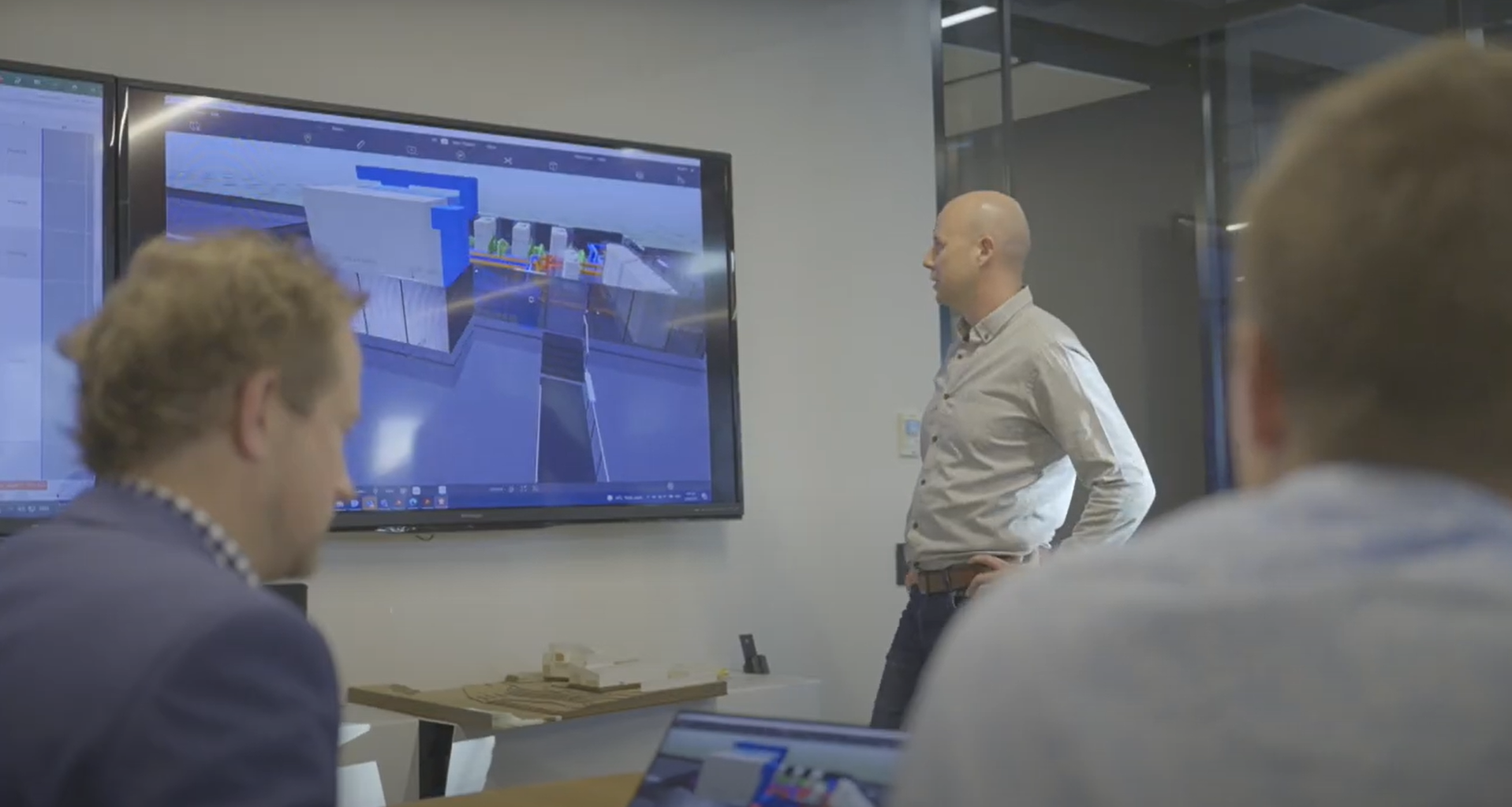

Reality capture is the process of creating digital representations of physical facilities using technologies such as laser scanning, photogrammetry, and sensors. For safety reporting and documentation in facility management, reality capture provides accurate, up-to-date 3D models and data that can be used to identify, assess, and monitor potential safety hazards. Reality capture enables facility managers to document existing conditions, track changes over time, and create detailed records of safety-related features and issues. The resulting digital models and data can be integrated with Building Information Modelling (BIM) systems to provide a comprehensive view of the facility’s safety status. This integration supports more effective safety management, facilitates compliance with regulations, and enhances decision-making processes throughout the facility’s lifecycle.

Case studies

Uses and benefits for health and safety

- space

- Precise documentation of facility conditions: Real-time data collection enhances decision-making and helps identify issues like structural damage or equipment wear, aiding in preventive maintenance and safety assessments. It also generates accurate as-built models for design, retrofitting, and expansion projects.

- space

- Remote monitoring: Reduces the need for physical presence on site and enhances collaboration among teams, while providing better access and visualisation of safety-critical areas and equipment.

- space

- Streamlined safety inspections and maintenance planning: Workers can familiarise themselves with the facility and identify the tools and equipment they will need before going on site.

- space

- Historical record: Regular reality-capture updates provide an ongoing record to document construction and maintenance activities, which can be used to demonstrate compliance with organisational and regulatory requirements.

Technology/techniques

Reality capture for safety documentaiton and reporting typically employs a combination of technologies. Laser scanning, using LiDAR (Light Detection and Ranging) sensors, creates highly accurate 3D point clouds of the facility. This is particularly useful for capturing detailed geometric information about structural elements and potential hazards. Photogrammetry, which constructs 3D models from multiple photographs, can provide textured models that are easier to interpret visually. Drones equipped with cameras or LiDAR sensors offer a means to capture data from hard-to-reach or hazardous areas, such as roofs or tall structures. These technologies can be supplemented with 360-degree cameras for creating immersive visual records of spaces. The data from these various sources can be combined and processed using specialised software to create comprehensive 3D models. These models can then be integrated with BIM systems, allowing for the addition of metadata about safety features, hazards, and inspection histories.

Model/data requirements

Effective use of reality capture for safety reporting requires a comprehensive approach to data management. The 3D models should be of sufficient resolution to identify potential safety issues, typically with an accuracy of ±5mm for internal spaces. Models should include all relevant structural, architectural, and MEP (mechanical, electrical, plumbing) elements that could impact safety. Metadata should be attached to model elements to indicate safety-critical features, inspection histories, and potential hazards. Regular updates are crucial to maintain the model’s relevance, particularly after renovations or significant maintenance activities. Integration with existing BIM or facility management systems is important to ensure consistency of information across different facility management functions.

Hardware and software requirements

Hardware requirements for reality capture include high-resolution laser scanners, drones with integrated cameras or LiDAR sensors, and high-quality digital cameras for photogrammetry. For processing and managing the captured data, powerful computers with high-performance graphics capabilities are necessary. Software requirements typically include specialised reality capture processing software such as Autodesk ReCap or Bentley ContextCapture, as well as BIM software like Revit or ArchiCAD for integrating the captured data into existing facility models. Additional visualisation software may be required for creating immersive views or fly-throughs for safety training or communication purposes. Cloud-based storage and processing solutions can be beneficial for managing the large datasets involved in reality capture.

Contract/procurement implications

When contracting for reality capture services for safety reporting, it’s crucial to clearly define the scope of work, including the areas to be captured, the required level of detail, and the frequency of updates. Contracts should specify the deliverables, such as point cloud data, 3D models, and any derived safety reports or visualisations. Data ownership and usage rights must be clearly defined, especially if the captured data will be integrated with existing facility management systems. The contract should address data security and privacy concerns, particularly for sensitive areas of the facility. Quality assurance measures should be specified, including accuracy requirements and validation processes. If the reality capture is to be performed in-house, procurement of equipment and software should consider ongoing support and training needs. For either in-house or contracted services, it’s important to ensure compatibility with existing systems and to plan for the long-term management and updating of the captured data.

Roles and responsibilities

| Facility manager | Define requirements for reality capture in the context of safety management, and oversee the integration of captured data into facility management processes. |

| Safety officer | Use reality capture data for safety assessments, inspections, and reporting. Provide input on safety-critical areas that require detailed capture. |

| Surveyor or reality capture technician | Operate scanning and imaging equipment, ensuring comprehensive and accurate data capture. |

| BIM manager or Data processing specialist | Process raw capture data into usable 3D models and integrate these with existing BIM or facility management systems. |

| Maintenance team or Contractors | Use BIM model and reality capture data for planning safe maintenance activities and update records following interventions. |

Training requirements

Training for reality capture in safety reporting should cover operation of capture equipment, data processing techniques, and integration with BIM systems, but only a small number of people will need this specialist knowledge and it may be contracted to specialist service providers. Facilities management staff probably do not need to operate data capture equipment, but will need training on how to interpret BIM and capture data in the context of operation and maintenance, including data management practices and the use of BIM visualisation tools for effective communication of safety information.

Future directions

Future developments in reality capture for safety reporting are likely to include more automated capture processes, potentially using autonomous drones or robots for regular facility scans. Artificial intelligence may be employed to automatically identify potential safety issues in captured data. The integration of IoT sensors with reality capture technologies will enable real-time monitoring of safety-critical parameters, providing a dynamic layer of information over the static 3D model. The wider introduction of reality capture tools, such as LiDAR scanners on mobile phones, will make frequent, small-scale updates more feasible, allowing for more continuous monitoring of facility conditions. Augmented and virtual reality technologies will likely play an increasing role in safety training and hazard communication, utilising these more accessible and frequently updated models.