City Rail Link: BIM for safety on Auckland’s City Rail Link project

Summary

On the City Rail Link project in Auckland, New Zealand, the project team has utilised BIM in various ways to improve safety planning, design coordination, and worker training. Using 3D models, point cloud data, virtual reality, and on-site digital tools, the team has been able to identify and mitigate potential safety hazards, standardise tunnel signage, provide immersive training experiences for workers, and enhance driver awareness. The approaches used on this large-scale, complex project can be adapted and applied to projects of any size, demonstrating the versatility and value of BIM in promoting safety in construction.

This presentation was given by Dean Burke, Technical Director of Digital Engineering at WSP, at the BIMSafe Beyond the Blueprint event in Auckland.

Background

The City Rail Link project is a 3.5-kilometer twin tunnel underneath Auckland’s city centre, which also includes the construction of three new railway stations. The project’s large scale and complex nature, involving tunnelling, station construction, and integration with existing infrastructure, necessitated innovative approaches to safety management. The project team recognised the potential of BIM to address these challenges and implemented various strategies to use its capabilities.

Video

Approach

The project team employed BIM in several ways to enhance safety:

- Safety in Design (SiD) reviews: SiD reviews were conducted regularly for each design package, with potential hazards captured in the SiD Register and BIMtrack. For the structures discipline, the SiD register was linked with model components using Revit families, enabling hazard identification in 2D and 3D elements on design drawings.

- Tunnel signage standardisation: No standards existed for tunnel signage in New Zealand, so the team developed 3D models using various sources from Australia and New Zealand. Visualisations were shared with stakeholders for approval. This work led to the creation of new tunnel signage standards for New Zealand.

- Noise enclosure spatial proofing: BIM models and point cloud data were used to accurately model noise enclosures, plan crane operations, and stage construction activities, minimising risks to workers and the public in a complex environment with associated with excavation and heavy equipment operating in close proximity to live streets.

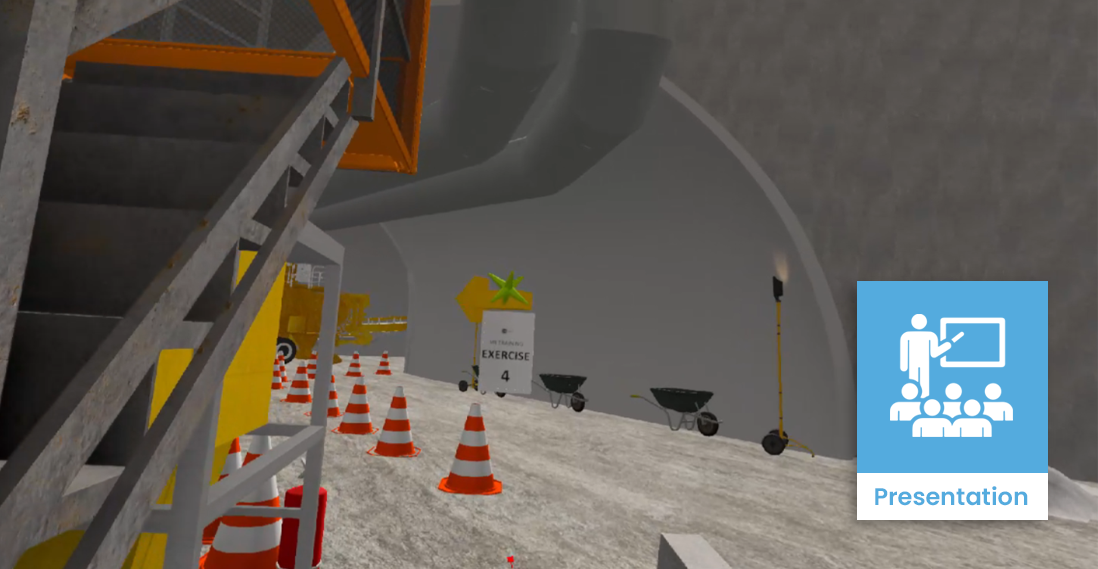

- Virtual reality training: A VR environment of the mine tunnels was used for worker inductions, reducing the need for on-site training in hazardous environments.

- Driver awareness videos: Drive-through line-of-sight and driver awareness videos were created using BIM models, to familiarise train drivers with construction staging and potential hazards, and ensuring they were well-prepared for the changing conditions during the construction phase.

- On-site digital transformation: Digital totems, tablets, and AR/VR were used on-site to provide access to the CDE, BIM models, drawings, and safety registers, enhancing communication and collaboration.

Health and safety benefits

- Improved hazard identification: By linking the SiD register with model components, the team could effectively identify, communicate, and mitigate potential safety hazards throughout the design process.

- Standardised tunnel signage: The creation of 3D models for tunnel signage led to the development of new standards for New Zealand, ensuring clear and consistent emergency wayfinding for tunnel users.

- Enhanced spatial coordination: Combining point cloud data with BIM models allowed for accurate spatial modelling of complex sites, such as the Mount Eden station. This enabled the team to plan, stage, and phase construction activities while minimising risks to workers and the public.

- Immersive training: Virtual reality environments of the mine tunnels helped workers familiarise themselves with the site conditions and emergency procedures, ensuring they were prepared for the work site and reducing the risk of accidents and injuries during the actual construction. Similarly, using videos for the driver training helped prepare them for risks associated with operating trains through active construction zones, ensuring a safer environment for both drivers and passengers.

Lessons learnt

BIM is scalable

While the City Rail Link project is large and complex, the BIM methodologies used can be adapted and applied to projects of any scale.

Integration of technologies provides additional opportunities

Combining BIM with point cloud data, virtual reality, and other technologies provided a more comprehensive understanding of potential safety issues and facilitated more effective mitigation strategies. This integrated approach to safety management builds on the strengths of each technology, resulting in a more robust and effective safety program.

On-site digital access is valuable

The use of digital totems, tablets, and AR/VR on-site allowed workers to access the latest project information, BIM models, and safety registers directly from the job site. This enhanced communication and collaboration among team members, leading to more informed decision-making and faster issue resolution, while reducing risks that would otherwise be associated with moving back and forth through the site to access information at the site office.